By Cassandra Balentine

While the fate of print is debated by many, the general consensus is that packaging isn’t going anywhere. Therefore, it’s an appealing market for print providers of all sectors to target. Further, the use of digital print enables shorter runs and customization.

Many existing digital production devices on the market are capable of producing some form of folding carton.

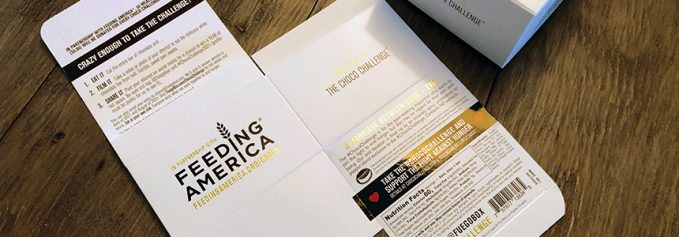

Above: K-1 Packaging Group is a CA-based print business that offers digital folding carton printing services.

“Digital provides an opportunity to prototype new products and design them to ensure maximum shelf appeal. Also, digital printing can enable versioning/personalized products so that brand owners can more effectively target their audience as well as the security features the market is now demanding,” comments Charlie Lahr, manager, inkjet solutions, Komori America.

Functions for Folding Cartons

Substrate support, color gamut, and quality are essential factors a press must offer to successfully produce folding carton packaging.

Ed Pierce, product marketing manager, Fujifilm North America, Graphics Systems Division, suggests first considering substrate breadth when adding this application. Is the press capable of running the same substrates typically required in this segment? Secondly, look at color gamut and the ability to easily reproduce brand colors at the right price point. A third consideration is the quality of the output and a presses’ ability to effectively produce detailed images, vignettes, small font text, and easy-to-read barcodes. Finally, it’s important to be able to fit into the same production and finishing environment, making the introduction of a digital press seamless to both the print provider and the print buyer, suggests Pierce.

Dan Maurer, VP, digital print, Americas, Heidelberg, feels that reliability, uptime—and ultimately, throughput—are essential functions for a press to successfully produce folding carton packaging. “Folding carton producers and decision makers are conditioned from their present analog presses to focus highly on lean manufacturing practices and thus, maximum uptime in their purchasing decisions,” he explains.

Maurer also notes color gamut, accuracy, and consistency as essential considerations. “Folding carton manufacturers must be able to achieve PMS colors accurately and reproduce them within tight delta Es throughout a production run and also on follow-up runs. Unlike commercial work where two or more pieces may not be viewed side by side, folding cartons are viewed on the shelf and color shifts cannot happen.”

He explains that cartons produced digitally need to match the PMS color specification and hold it tightly. “Additionally, since digital carton SKUs are often run as test samples or for press checks prior to longer offset runs they need to match the same appearance and durability factors as offset. This includes not only color and screening appearance, but also coating compatibility and using the same substrates.”

There are some roadblocks for digital print providers interested in producing folding cartons with their digital presses.

Lahr says limitations typically involve the type of substrate that can be used along with speed. “As it relates to the Komori Impremia IS29, 24 point is its thickness limitation, but this meets most folding carton specifications. Speed remains an area of limitation as packaging printers need to pull more work from offset to meet the growing demand for fast turnaround times. As speed increases, so will the crossover point between the two print technologies.”

Historical limitations included quality of output, color gamut, color repeatability, and finishing options. “Today however these limitations have essentially been overcome,” says Pierce, noting that the J Press 750S from Fujifilm exceeds the quality of offset and delivers a wide color gamut and makes repeating color as simple as hitting the print button. “Not only does the J Press fit into most existing finishing lines but there are also a range of specially formulated coatings available at market based pricing should a print provider have the need for these products. Another perceived limitation is the speed of the press, but each new generation continues to push the envelope and introduces increases in productivity.”

Cost per sheet compared to analog technologies—which have also made technological progress—is another challenge for digital. Maurer says the crossover point of job length has become quite short. “Folding carton manufacturers must understand the marketing advantages that a digital press can provide them—short turnarounds, multiple SKUs, variable content, and overall easier operation.

Uptime as well as reliability—whether with toner or liquid electrophotographic or inkjet presses, each with their unique engineering challenges—is another consideration.

A further challenge in digital folding carton production is gluing the cartons on a folder gluer, which can involve significant makeready time and overage cartons for set-up, sometimes defeating the advantage of digital printing, points out Maurer.

Embellishments and Effects

There is a spotlight on high-value applications, including special effects, toners/inks, and other embellishments.

“Enhancements and embellishments play an ever-increasing role in creating value for every printed folding carton piece,” says Pierce.

Because run lengths continue to trend shorter, each printed piece must provide additional value and help brands stand out. When considering a digital inkjet production press, this becomes important along with how well the printed output performs with both aqueous and UV coatings and specialty spot coating processes and embossing,” says Pierce.

Lahr agrees, noting that brands continue to look for ways to make their products stand out with maximum shelf appeal, so value-added print enhancements and embellishments are a must in digital printing. “Whether done inline or offline, brand owners look to new coating techniques to enhance the design of the package,” he offers.

Maurer believes print enhancement is still a niche market. “They look fantastic, but there is the challenge of selling the features to the client. There are a few folding carton manufacturers that specialize in high-end cosmetics and consumer products who do take advantage of it. What would be more beneficial is if more digital presses offered inline coaters and compatible coatings, or double coaters that can both protect the carton and provide spot effects.”

The COVID Effect

The COVID-19 pandemic continues to influence nearly every market and industry worldwide, including packaging.

COVID-19 has had both a positive and a negative effect on the digital folding carton segment. “Companies’ capital budgets were locked down so the investment in new technologies, like digital presses and finishing, were reduced. This is especially true of commercial printers who are trying to expand into digital folding carton,” says Maurer.

However, the pandemic also brought empty store shelves, and packaging converters were doing all they could to keep up with the demand. “With this came along more marketing opportunities for more SKUs, which are ideal for digital packaging print engines along with variable print content for security/anti-counterfeiting and personalization marketing opportunities,” says Maurer. He adds that COVID-19 also brought along more online purchases, and although these are primarily shipped in corrugated boxes, companies are using product cartons for more opportunities to market to their customers.

Pierce says COVID-19 has driven folding carton manufacturing from China and other overseas locations back to North America. “Packaging companies have been at capacity with the onslaught of orders. There is no reason to think this trend will reverse as many of the issues related to an international supply chain have become very real,” he offers.

Additionally, as companies continue to shy away from large outlays for what most often ends up as excess and obsolete inventory, Pierce believes print buyers will continue to favor shorter runs with faster turnaround times and reorders. “These realities will most certainly impact the growth for production digital printing.”

Lahr also feels that the COVID-19 pandemic has accelerated the move to digital. The pandemic has prompted the demand for quicker time to market as well as the ability to produce short-run and personalized packaging. “In the packaging world, it is all about speed to market and that is where digital pays dividends,” he states.

Packaging Professionals

Folding carton production is advancing with the latest digital printing technologies. Many market drivers make the ability to cost-effectively produce short runs of folding carton applications attractive to print providers, packaging converters, and brand managers.

One company well versed in these benefits is K-1 Packaging Group, a family owned and operated business in CA. The company started as K-1 Printing & Graphics in 1993. It employs a full-time staff of 130. Its two manufacturing facilities in Southern CA have a combined area of 180,000 square feet. The City of Industry, CA facility serves as the company’s administrative headquarters as well as the manufacturing site for folding cartons and litho mounted corrugated boxes. Its Pomona, CA facility is where pressure-sensitive labels, shrink sleeves, flexible packaging, and stand-up pouches are produced.

In addition to its U.S. manufacturing locations, K-1 Packaging Group operates a supply chain procurement center in Shenzhen, China. This was established in 2006 as an ancillary service to facilitate the procurement of materials and components for customers.

Packaging Evolution

At its beginning, the company produced envelopes, letterheads, and business cards with a small format offset duplicator. At this time, the company would take on bigger commercial printing projects, but outsourced them.

Recognizing the threat of digital technology in the late 1990s, the company made a strategic pivot into the packaging space by offering folding cartons. “The initial steps were tough because we were lacking in both financial means as well as technical knowledge,” admits Mike Tsai, president, K-1 Packaging Group. “It took a lot of grit and years of persistence to slowly get established in the packaging space.”

K-1 Packaging Group’s perseverance paid off. Over time, the company added more capabilities and products to its portfolio. Today its product offerings include folding cartons, litho-mounted corrugated boxes, pressure-sensitive labels, shrink sleeves, flexible packaging, as well as stand-up pouches.

These are produced using sheetfed offset printing, sheetfed digital printing, narrow web flexographic printing, narrow web digital printing, and a host of post-press and finishing capabilities.

Specifically, the company operates offset presses from Koenig & Bauer, flexogrpahic presses from Mark Andy and Nilpeter, and digital narrow web presses from HP Indigo. It recently invested in a Landa S-10 printing platform. “Regardless of its make and the technology behind it, each piece of equipment serves a purpose and can produce certain work, which perhaps cannot be done as well or efficiently when produced on other equipment,” shares Tsai.

Nano Technology

The company started evaluating cutting-edge digital printing technology from Landa in 2017. The purchase commitment was made in 2019. The Landa S10 press was chosen to address the ever-increasing number of short-run folding carton jobs. “Landa’s speed and efficiency at producing back-to-back, short- to medium-run jobs from small sheet sizes up to the B1 format is its biggest advantage. The short makeready time, in conjunction with its rated speed of 6,500 sheets per hour, greatly enhances our daily throughput of short- to medium-run jobs.”

Tsai says the press has consistently demonstrated the ability to reproduce colors accurately on repeat works, something that is occasionally a struggle in offset printing.

The company continues to benefit from improvement in overall productivity brought about by the Landa. Shorter runs can now be produced more efficiently, freeing up offset presses to produce larger volume jobs. Another unexpected benefit is the press’ ability to match Pantone colors well. “We have eliminated the need for spot color inks which would otherwise be required if the job were printed on the offset press,” he shares.

The Landa prints on all common substrates it uses for folding carton production, including SBS, CCNB, and other specialty substrates. The inks used are proprietary, water-based Landa NanoInk.

The package printer recently completed a 185,000-piece run of folding cartons for an essential oil product. The production quantity was spread across 25 versions. While all the versions shared the same folding carton structure, each had a different graphic design and required different quantities. As a result, there were 25 separate eight-up press forms.

“We printed each press form successively one after another, with minimal pause in between. It is truly remarkable that we printed the entire job in just ten hours,” shares Tsai.

Improved Confidence

K-1 Packaging Group’s technical competencies along with the breadth of service, products, and capabilities rival that of much larger multi-plant companies. However, its responsiveness and agility are that of a smaller and more nimble organization.

Unlike many industry sectors and businesses that have been hard hit by restrictions brought on by the pandemic, K-1 Packaging Group actually experienced record sales in 2020. Frenzy buying after the national emergency announcement, along with sustained surge in demand for packaged food, personal care, and health products, all contributed to growth experienced in 2020.

“Having experienced the benefit of digital printing, first with the HP Indigo for production of pressure-sensitive label and flexible packaging, followed by the Landa for production of folding cartons, we are fully convinced that in years to come, digital technology will continue to gain relevancy and make an impact in the packaging industry, but at an even faster pace. As we expect K-1 Packaging Group to remain on its trajectory of fast growth over the next five years, we will be keenly evaluating additional digital technology in areas of printing as well as finishing to help us support this growth,” concludes Tsai.

Challenge Accepted

The press did come with a learning curve. “The volume of technical knowledge our staff has had to acquire to gain proficiency on the press has been the greatest challenge we faced during implementation. Aside from the mechanical aspects of sheet feeding, transport, and delivery that shares commonality with sheetfed offsetting printing, all other functions are different and need to be learned from the ground up.”

Luckily, training for press and prepress personnel starts well before the installation with self-paced, web-based lessons across a multitude of topics. After installation, service engineers and instructors work intimately with the company to train staff on operation, maintenance, and troubleshooting.

“This on-site close support continues even after commencement of production. During this time, Landa’s service engineer in effect work as part of the press crew, contributing to the production of live jobs. Needless to say, the amount of support and resources that Landa has poured into this installation has been confidence inspiring,” offers Tsai.

High-Value Applications

The role of digital print in the folding carton production market is promising. As brands look for just-in-time manufacturing, heightened customization, and more SKUs, digital printing presses are poised to serve. However, it is essential to understand the limitations of your press and profit potential for this type of work.

For more information on folding cartons, check out our recent webinar on the topic, featuring Tilia Labs and Komori. Visit dpsmagazine.com and click the Webinar tab to access the archives. dps

Mar2021, DPS Magazine