By Melissa Donovan

Photobooks present both opportunities and challenges to digital print providers. A purely digital and in demand application, it must be high quality and long lasting. The production process of a photobook is intricate and made even more so if automated finishing tools aren’t used. Without these tools, room for error increases. Costly mistakes not only hurt the bottom line, but a company’s reputation. To remedy this, implementing an automated finishing device into a digital workflow is essential.

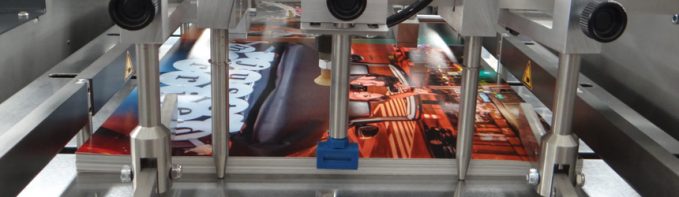

Above: The feed hopper in the fastBook Professional from Imaging Solutions.

Open Opportunity

The opportunity for book production is propelled by the advent of social media and smartphones, consumers constantly look for ways to turn digital media into hard copies without a separate visit to a brick-and-mortar store.

“Web-based storefronts have rapidly replaced traditional photo processing centers, film drop centers, and direct mail ordering. The demand for prints in all sizes and textures—as well as photo albums in hard cover, soft cover, or custom casing—has grown proportionally,” explains Will Frank, marketing specialist, Standard Finishing Systems.

Photobooks are used to showcase weddings, anniversaries, and birthdays. “They’re perfect for any short-run documentation that needs a high-end look and feel to make a unique statement,” shares Joe Bondonna, product manager, Spiral.

With the vast amount of usage options, photobook production is on the rise. “The ability to create and bind on demand, short-run hardcover books has steadily increased over the past five to ten years. Most of the increase we see comes from the short-run digital print market,” says Jeffrey Kohn, president, Pro-Bind.

Print operations properly equipped in both machinery and mindset are able to successfully and profitably offer photobooks to customers. According to Jeff Truan, global business development, Nobelus, if a shop is digitally driven with good workflow, finishing capabilities, and additional capacity, it is considered an ideal fit.

Jim Kaeli, solutions manager, book technology and hardcover, Muller Martini, says traditionally, there are three tiers of manufacturers engaging in the photobook space—high-volume branded manufacturers, high-volume non-branded manufacturers, and storefronts.

High-volume branded manufacturers are internet-based retailers conducting their own photobook manufacturing that features lifestyle brands and logos. High-volume non-branded are also web-based, but manufacture and fulfill large volumes of photobooks that are then branded with private labels. Storefronts are also marketed on the internet and carry the brands of their storefront. However, the actual product is manufactured by a third party.

Dianne Moralee, sales director, Taopix Limited, divides photobook creators into two categories—those designed by professional photographers on behalf of their clients and those designed and purchased by consumers and amateur photographers.

“The market is pretty well defined by these two distinct groups with traditional professional labs servicing the professionals, offering a high-quality range of products, usually at a premium price point. Online photo retailers tend to focus more on the consumer by offering fast turnarounds and competitive pricing,” explains Moralee.

Traditional printing companies are branching out into the business-to-consumer (B2C) market, she admits. These organizations operate with a separate brand identity while running successful business to business (B2B) and B2C businesses under the same roof. Moralee says B2B2C is another avenue being pursued. “By becoming purely a manufacturer, the printer focuses solely on producing high-quality books for the consumer that are being marketed and sold by a brand, retailer, or other third-party with a presence in the consumer market,” she shares.

“Digital printing and binding make it possible for printers and other service providers to offer personalized photobooks for virtually any B2C or B2B related event, milestone, or information requirement. The turnaround time and relatively low cost means that providers can offer test runs as well as no-charge samples to prove a photobook’s value,” advises Brigitte Peleman-Vantieghem, CEO, Photomore, a Peleman Industries Group.

Addressing Challenges

While the opportunity for photobook creation is large, print providers still need to overcome certain challenges. A streamlined and efficient workflow is critical for a smooth production process. Investments in printing, finishing, software, and media are justifiable if they ensure profitability.

“Profitability in the creation of photobooks requires an efficient and consistent manufacturing process. The materials used in photobooks, particularly premium books, are expensive and mistakes can be costly,” admits David Williams, area sales manager, NA, Imaging Solutions AG.

“Reprints of products that fail quality checks due to print or finishing create exceptions to the normal workflow and loss of profit due to redundancy of labor and material costs,” agrees Frank.

The workflow running the entire operation should be addressed immediately to avoid errors. “Because of a photobook’s one-off nature, production success can only be achieved through a highly efficient workflow, one that’s typically barcode driven. And, for just about every photobook manufacturer that workflow is proprietary. This means that a significant investment is made in IT infrastructure, which then enables total control of schedules and outcomes,” explains Kaeli.

In terms of output, quality is a must. “Quality is much more exacting than that of general commercial print. These are products that show loved ones and special times—clients expect the best in product quality—period,” recommends Truan.

In regards to finishing, the traditional process of binding books was never cost effective, especially for runs as short as one. “Because of its complexity, bookbinding development—especially the binding of hardcover books—has trailed the capabilities of digital print solutions. These methods were highly manual, tediously slow, and relatively expensive. As such, consumers and manufacturers desiring a premium quality bookend were relegated to expensive hardcover books or had to compromise for perfect bound and saddle stitched books,” explains Ric Bloch, managing director of NA, Photobook Tech USA.

“On demand production allowing for shorter turn times and quality of prints has always been the Achilles heel. Many printers didn’t want to invest in larger binding systems if their current volume couldn’t justify the investment,” says Kohn. Smaller, affordable tabletop binding systems and software extend possibilities for print providers.

“Relevant to finishing, it is critical to have in-house, single-sided lamination with significant nip pressure to allow top-quality images to be finished correctly. It also helps to have variable data foiling as foil is currently desired in the personalized consumer market. Additionally, if the proper laminate films are not used, delimitation becomes a large issue and a quick way to go upside down on revenue due to returns and/or remakes,” shares Truan.

Outside of the production workflow, time considerations are critical. “The production process of a photobook can be tedious, especially if the end user is not given tools to organize and design his/her project independently. Having the back and forth between the consumer and the printer to discuss layouts and finalizations adds a lot of time to each project, making the whole production process expensive and inefficient,” says Marion Duchesne, CEO, Mediaclip Inc.

Marketing is another factor. “In order to maximize profitability, print providers must be able to offer a product line diverse enough to reach a large audience and keep product offerings fresh, while at the same time minimizing the amount of inventory and substrate offerings,” adds Frank.

When to Consider Finishing

While print providers may already own presses that can output photobooks, it is finishing that typically requires some attention. Adding an automated finishing device in particular can be the difference between a successful and non-successful implementation. Most vendors agree that integrating automated finishing right away is a good decision.

Sacha-Vittorio Paolucci, commercial director, C.P. Bourg, recommends that print providers add automated finishing immediately, citing that 90 percent of photobooks are produced in quantities of one to three units and automated on demand production provides both flexibility and quick turnaround time for book of one production.

“Automation in finishing is important in photobook production to minimize waste, maximize quality, and improve productivity. By utilizing reliable, accurate automation, you can ensure consistent production quality, eliminating subjective strings made by varying operators from shift to shift, day to day, or machine to machine,” says Frank.

Williams believes that without automation it is almost impossible to offer competitive pricing or consistency in quality. “It is also too easy to get overloaded and start shipping late. Before investing marketing dollars to build a customer base, there needs to be a scalable manufacturing system in place to make sure those customers can be satisfied,” he recommends.

“Without automation for creation as well as finishing, the production process for photobooks is lengthy,” says Duchesne. “The lengthier the process, the fewer photobooks your business can print, the fewer photobooks you will print, the more you will have to charge for orders to offset your costs, and lastly, the more that photobooks cost, the less likely consumers are to order from you,” she explains.

Automating Finishing

Daily Printing, based in Plymouth, MN, is a 65 year old commercial printer with a hand in digital technologies since 2007. It offers web to print, variable printing, and other digital printing based services, along with portals and digital delivery. Established in 1950, it staffs over 70 employees.

Over the last few years, the print provider ramped up its digital work thanks to its Xerox Corporation iGen 150 Press, which allows for jobs printed in small quantities. Unfortunately, its finishing equipment had a hard time keeping up.

“We would run 40,000, 96 page catalogs on a stitcher and then need to stitch 15, 20, or 100 digital books. It would often take us several days before we could have anything completed, making it inefficient and time consuming for us to be reactive to our digital customers,” shares Peter Jacobson, CEO, Daily Printing.

In response, the print provider visited a demonstration center and decided to implement a new Xerox iGen 150 inline with a Bourg Bleed Crease Module BCM-e, Bourg Booklet Maker BM-e, and Bourg Square Edge SQE with the Xerox IntegratedPLUS Finishing Solution. Jacobson says the company selected this configuration due to its quality of construction, uptime, and ease of use.

Since implementation, Daily Printing’s production workflow has become highly efficient. The Xerox iGen 150 inline finishing device saves a minimum of one day in process time and reduces production time by three to four hours after machine setup.

The solution opens up opportunities for new services. “Because we keep everything together and collate and stitch inline, we can include variable data and customer data throughout the book. It gives us the opportunity to grow because now we can offer personalized books and catalogs as a service without any of the issues that used to limit us,” shares Jacobson.

Production Promises

There is a strong demand for photobooks. To keep up, print providers consider print quality, finishing power, and workflow. Traditional bindery techniques can slow the process and lead to manual errors. Digital is ideal for the most common photobook orders, which are mostly comprised of short runs and variable data.

Jan 2018, DPS Magazine