By Melissa Donovan

To avoid an idle press, digital print providers are often on the lookout for print jobs that complement their existing services. Package design and prototyping is one consideration. There is great opportunity in this segment, especially for short or ultra-short runs. Demand is high and continues to grow as brand owners recognize the appeal of fresh new designs, which shorten sales cycles and require constant updates to packaging.

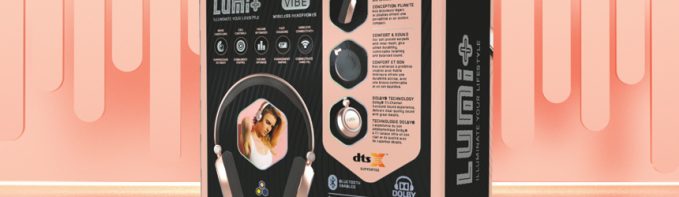

Above: According to Esko, WebCenter has packaging at its core. It understands all aspects of successful packaing—its shape, the importance of brand colors, and offers control of all necessary content.

Strong Demand

Gone are the days where a package with a static design can remain on a shelf for years on end without changing. Brands from every industry understand that packaging must be dynamic to generate attention.

“There is a growing trend toward shorter runs, due in part to the maturing market in digital print, which means more SKUs and therefore a greater demand for designs. Furthermore, brand owners are increasingly willing to invest in distinctive packaging design to add value to their brands and increase product sales,” says Chris Rogers, solution marketing manager, Esko.

With brands continually refreshing and reinventing designs to create new SKUs and looking for new ideas to stand out on the shelf, there is a growing need for package design and prototyping services. “They are very useful for a customer to test the market and to create products that perfectly suit users’ needs. Communication tests and market validations are easier to manage thanks to these unique tools that break down the barriers of traditional production,” explains Giuseppe Prioriello, founder/CEO, Packly.

Multiple parties including brand owners, marketing and/or creative agencies, print providers, and packaging converters play a role in this evolution. Benson Tung, product manager, Packmage Technology Co., explains that the increase of small-scale personalized consumption is commonly derived from small or entrepreneurial enterprises. These brands do not have their own packaging department. So, as it is an unfamiliar field to them, the service needs to be outsourced.

“Demand is driven mostly by the growth in local and boutique businesses that don’t have the packaging and design resources of larger consumer package goods,” agrees Ed Pierce, product marketing manager, Fujifilm North America Corporation, Graphic Systems Division. He also suggests influence from agencies looking for creative ways to take advantage of the new production abilities found on high-end production inkjet presses and digital embellishment assets.

In addition to brand owners under pressure to increase product versioning and marketing service providers or agencies looking to showcase their creativity, Sebastien Stabel, sales manager, carton packaging, EMEA, Xeikon, believes print providers wanting to meet just-in-time delivery requirements and add value by supporting clients in their desire to stand out are another piece of the puzzle.

Packaging converters are also part of the demand. “Packaging converters find these services critical to their client relationships and the implementation of digital printing is an enabling technology for prototyping and market testing. We see a cottage industry developing here, as experienced package designers fill the supply gap for services with digital print partners,” shares Rick Mazur, worldwide director, market development, packaging/labels, Eastman Kodak Company.

In-House Benefits

Initially, a service provider might want to only handle the design or printing—and not both. This is partly due to weariness over fully committing to a new venture as well as investing more time and money. While it’s a fair concern, avoiding outsourcing completely means bigger rewards in the long run for both the customer and the service provider.

For the customer, Tung explains the advantages. “In traditional business, packaging design and production are separate—customers first look for design companies, and after determining the design plan, customers look for production companies again. This increases the total cost. Integrating design and production into a comprehensive plan greatly improves efficiency and cost.”

Positives to bringing the entire service in house for the service provider include a decrease in time and cost as well. Specifically, turnaround time and especially if any rework is needed. “Increased quality and reduced rework is a large benefit to bringing this activity in house for prepress suppliers. The savvy prepress companies understand that taking control of this process reduces their production costs and turnaround downstream,” says Marc Welch, director of strategic accounts, GMG.

Control is essential. According to Brian Dollard, director, strategic planning and business development, commercial and industrial printing business group, Ricoh USA, Inc., in-house production makes both cost and quality transparent and controllable. Take for example conducting A/B testing to help optimize a company’s packaging approach. “If outsourced, the approach is cost prohibitive because it requires two separate jobs for the testing phase and then a third, larger job once a design is settled on.”

Design—and by extension, color—is well managed if kept in house. “By handling production in house the service provider not only provides the entire spectrum of services—design through end production—but can also design to the strengths of in-house production assets and own the output result,” shares Pierce.

“By offering packaging and prototyping services in house service providers ensure immediacy, responsiveness, improved communication, and streamlined technical processes. As a one-stop shop, the print provider is more tied and indispensable to its clients, which can benefit planning while also providing the customer with the reassurance of more accountability,” explains Nick Gilmore, CEO, Creative Edge Software.

It is important to foster a relationship with the customer. Indeed, if they are creating multiple versions, seasonal offers, and regular promotions, it is essential that a service provider understand and really get to know the customer, as they will be dealing with them on a regular basis.

“One of the biggest benefits is maintaining the relationship between the client and supplier. By managing the whole process internally you not only ensure the client has one point of contact, but you also get to know that client better and potentially even develop a mutual understanding,” comments Stabel.

Understanding Limits

Digital printing may be ideal for short- and ultra-short runs, but sometimes there are limits. It is important that service providers execute a cost analysis for each job prior to running it. Packaging and prototype design and production may be lucrative, but it can also offer margins for error that effect the bank account.

Dollard points out that while digitally printed packaging at short- and ultra-short runs is feasible, the finishing end of the process is important and requires additional resources. He advises that a printer conduct a careful return on investment analysis before taking on short-run work.

“When a compelling prototype is created, the typical response of the client is, ‘this looks great, I need a hundred of these for a marketing meeting next week.’ Suppliers are reluctant to tell a major client no. It is important for new prototyping suppliers to understand this and plan for it to happen—frequently. It is not uncommon for prototyping suppliers to produce hundreds and sometimes thousands of ‘prototypes.’ This blurs the lines of the definition of ultra-short runs,” adds Welch.

For this segment, the question becomes, what should the cut off be for short- or ultra-short run work? In Mazur’s experience, converters look at under 300 as ultra short and up to 5,000 as the cut off for short runs.

“In terms of production, there is no real cut off for handling ultra-short runs in house,” admits Prioriello. “However, there might be some bottleneck with the management of many short-run orders.”

When it isn’t feasible to handle an ultra-short run in house, production houses and design firms can collaborate to offer the best experience for the end user. An example would be when a short-run reorder needs to fill in a need for a longer run. To reprint a short-run length order on a conventional platform places enormous pressure on cost and profitability, according to Pierce.

Mazur says converters are building client-focused, cross-functional work teams with their design and trade shop partners to combine skills with structure design, substrate knowledge, data management, graphic, and digital production. The idea is to move projects efficiently through development, costing, and presentation to their clients.

With the constant reduction of turnaround times, effective collaboration is key. “Short runs often mean a job needs to be designed, approved, produced, and shipped in a matter of days rather than weeks. Therefore, efficient communication and project management is imperative,” explains Rogers.

“By installing the same systems for continuity and integrity of data, production houses and design firms can ensure they’re speaking the same language and there is no risk of design and specification misinterpretation,” shares Gilmore.

Supplementing Success

Tools that those looking to offer design and prototyping should consider include package design tools, production workflow tools, and on demand printing and cutting tools.

Self-service online packaging customization systems are helpful when it comes to improving efficiency, particularly in the communication between buyer and seller, according to Tung. These types of solutions should include a box type/material/process library, 3D virtual proofing, and automatic valuation functions.

“Primary customers have little knowledge of box type, need to know what the finished product looks like, and want to know the cost immediately,” explains Tung. The aforementioned tools address these challenges and without them efficiency is lost. “If the selection and pricing of each package requires professional structural engineers, the cost will be too high and it is difficult for service providers to even establish a team of structural engineers.”

New suppliers should find a way to include all of the following prototyping tasks, according to Welch, including structural, 3D software, prepress, cutting and scoring, laminating, finishing, and floor space. “Prototypes require folding, gluing, shrinking, and other complicated finishing operations. Most of this is done by hand and requires skilled labor to produce with the desired attention to detail,” he continues.

“For short-run productions, it is also necessary to have an effective digital printing and finishing plant. For instance, digital cutting tables or laser cutting tools are strongly suggested to deal with this type of production,” adds Prioriello.

“One of the biggest challenges and opportunities is in color management and building CMYK-based files from traditional flexographic/gravure files, ensuring the digital production can cost-effectively deliver projects and allow for production flexibility. Color management and software tools that automate job submission, preflight, job color match, and minimize job touches all contribute to streamlined production,” adds Mazur.

Packaging Welcomes Digital

Established in 1843, Zumbiel Digital’s—based in Hebron, KY—main service is paperboard packaging. Its 500,000 square foot space houses sheetfed lithography, web flexographic, and digital presses. A staff of 400 helps reach customers across Canada, Mexico, and the U.S.

In 2017 it added digital printing to its repertoire with the goal of minimizing the cost of producing folding cartons digitally. “We wanted to install a production digital line for large-volume, low-cost digital folding cartons. In doing so, we configured our digital press as a web-fed, continuous inkjet with inline die cutting and numerous analog flexographic print units for spot colors, overprint varnishes, and backside printing,” explains Ed Zumbiel, president, Zumbiel Digital.

It chose a Kodak Prosper 6000S as its introduction into digital. Several features enticed Zumbiel and his staff to pick this particular press. For example its speed—650 feet per minute in high-resolution mode, its web format, compatibility with coated paperboard, quality, achievable color gamut, economic ink cost, and 24.5-inch width.

Since the press was added primarily to satisfy high runs of folding cartons, Zumbiel Digital did not have prototyping services top of mind. However, once the Kodak Prosper 6000S was up and running, it was evident just how easy and economical shorter runs could be.

In response, its sales force started offering ultra-short run digital cartons to customers. These same customers were already utilizing Zumbiel Digital’s carton design services, so they were well suited for prototypes and sales samples. “Our equipment is ideal for ultra-short runs of a couple thousand cartons because we manufacture die tooling in house and stock most of the popular paperboards,” shares Zumbiel. He adds that its current cut off for handling ultra-short runs in house is 50 cartons.

Nestle Waters is a regular customer of Zumbiel Digital. It often requests small quantities of folding cartons with identical specifications to production cartons. Using the Kodak Prosper 6000S the output is a near match for the production cartons. For finishing, die cutting is generally used for small quantities, as it is more cost effective to build a die than cut prototypes on a plotter table, according to Zumbiel.

The machined samples perform exactly as the production cartons, particularly in terms of coefficient of friction and score bends. “This is ideal for new product launches involving automated carton filling equipment,” he continues.

Zumbiel Printing continues to experience success with its digital acquisition of the Kodak Prosper 6000S. The challenge, admits Zumbiel, is getting the word out about this new service.

Focus on Short Run

The Mid-York Press, Inc. is known for printing and producing folding cartons. In business since 1946, the Sherburne, NY-based company supplies products nationally to pharmaceutical, cosmetic, and food industries as well commercial printing services to local establishments.

In addition to several Heidelberg presses, the company works with an iGen 150 digital press from Xerox Corporation, which is equipped with an inline aqueous or UV coating unit. “A digital press is the number one tool for offering packaging design and prototyping. The Xerox iGen 150 delivers best-in-class packaging design and prototyping to our customers. With digital technology, we are able to speed customers’ time to market,” shares Thomas Revoir, digital packaging specialist, Mid-York Press.

Everything conducted digitally is considered short run at Mid-York Press. 5,000 sheets is the maximum for running through the machine, so it considers anything up to 10,000 cartons a short run. In Revoir’s opinion, some of the biggest demand for these short runs derives from boutique businesses with strong local roots.

“These companies are looking for local design and prototyping counterparts who can help them reach their specific delivery goals. The boutique businesses we’ve seen looking for these types of services include everything from specialty food companies and coffee shops to even distilleries and cosmetic companies,” he explains.

Attracting these types of companies to Mid-York Press is the business’ end-to-end capabilities. Offering packaging and prototyping services from design to production all in house is a huge allure to the end user because it saves the customer money, according to Revoir.

“By providing your customers with that cost savings you’re also giving them a competitive advantage and increasing the likelihood of their returning business. By decreasing the cost of production and the time it takes to produce it, we’re able to deliver true value to our customers,” he continues.

Extensive Opportunity

Packaging and prototype services are in demand for a number of reasons. Various interested parties from brand owners to print providers and even traditional packaging converters understand that dynamic packaging is here to stay. It extensively increases the need for design and production services for packaging and prototyping. dps

Oct2018, DPS Magazine