By DPS Magazine Staff

For practical and promotional reasons, many transactional- and marketing-based applications require card attachment services for mailings.

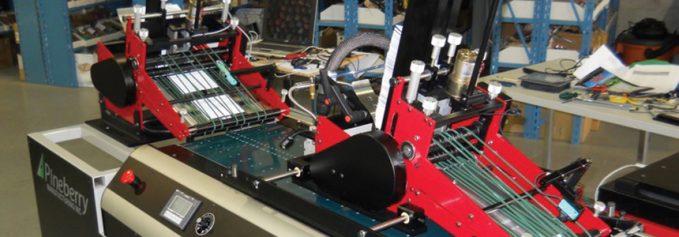

Above: Pineberry offers its Card Affixer CA 10000 operating system. Its touch screen controls allow for easy navigation and exchange of jobs.

Card attachment services are marketable to a range of prospective customers, including retail, telecommunications, airlines, hospitality, and financial institutions. “Some of these may already be existing clients for printed products so upselling should be looked at,” notes Steve Jarvis, sales and marketing manager, U.K., KAS Paper Systems Ltd.

With integrated solutions, print providers and data centers are able to act as end-to-end providers, delivering automated, inline, and efficient card attachment services. “For clients, this becomes a one-step, one provider service—one supplier delivering expertise, quality, and convenience,” shares Eddy Edel, VP, product management, BlueCrest Inc.

Automated solutions allow customers to increase efficiency and customization capable of offering unique services. “Customers often do not realize how beneficial and valuable their return on investment is on an automated card attaching system until after their purchase,” says Jovany Sanchez, marketing coordinator, Pineberry Manufacturing, Inc. “This allows the customers to generate high volumes of acquisitions through direct mail and other forms of distribution while saving money in the long term.”

Tools of the Trade

The demand for card attachment services and systems is strong as the market continues to evolve and a variety of organizations see cards as a way to stand out.

The card attachment market is advancing as more cards are sent through the mail. Examples include credit card-sized plastic driving licenses, health cards, loyalty cards, and solicitation cards,” says Edel. “The usage is large in scale and straddles both the transactional and marketing worlds.”

Jarvis points out that mail clients in increasingly competitive sectors are driven to seek ways to encourage and incentivize consumer brand loyalty with membership and reward cards. This is true for the hotel and airline industries as well as gyms and mobile phone providers.

To keep up with growing and evolving demands, systems providers continue to advance card attachment machinery. According to Sanchez, the introduction of robotics and new production lines keep up with large orders from various businesses that want to differentiate plastic cards from their competitors. “Additional collaterals and peripherals had to be created as demand increased through the trend of customizable products,” he shares.

Time to Invest?

Card attaching services may make sense for a print or data service providers doing a lot of mailing or promotional work.

Jarvis notices a trend towards print providers being asked to add value and provide a one-stop-shop solution. This means they must supply clients with not only all of their conventional print requirements, but any marketing material, including attached cards. “Print providers who over the years are under increasing pressure to reduce costs and improve margins have already brought prepress and finishing in house without too much difficulty and should be able to do the same with card attaching,” he offers.

Edel echos this sentiment, adding that businesses are always seeking new growth opportunities. “Right now, that vision is needed more than ever. The pandemic has quickly re-shaped operational strategies, placing increasing importance on the ability to flex to new markets. One such opportunity is card attaching.”

Card attachment systems make the assembly for finished cards look professional and durable for any transportation method. “Furthermore, the investment in automated affixing/tipping makes the job significantly easier, which promotes efficiency,” says Sanchez.

Of course, deciding where to spend a tightened budget is an important decision. Card attachment systems can come with a hefty price tag, upwards of $140,000 USD. Although exact costs depend on daily volumes and machine speed, as well as equipment configuration.

Jarvis points out that several considerations affect price, such as whether the carrier letter is printed offline on an existing printer or inline, where the card is personalized, the quantity of inserts, whether or not it requires coding and matching with the carrier letter, and if the end client requires a verification or reconciliation log or .csv file output of all coded documents that have been camera read and sent through the machine.

Automation and Evolution

Communications continue to evolve with consumer tastes and trends. The card attachment process is growing similar to the typical inserting process in mailing and fulfillment.

Traditionally, card attachment was done by hand, matching a unique ID number and the name on the card and the carrier letter. “As customer requirements changed and volumes increased, so did the attaching technology,” shares Jarvis. He explains that initially, magnetic stripes put on cards were read and matched with the carrier letter in addition to their primary function of being read by ATM machines and point of sale equipment. “Today we see much faster and more complex equipment as described previously.”

As card attaching increasingly resembles typical mailing applications, workflow integration and automation is key. “Effectively, more work can now be taken into the established mailing work-cell rather than requiring a separate team—and standalone technology—to handle the attachment element of the process,” shares Edel. “Businesses that were perhaps operating only at the insertion or sortation stage of card mailings can now offer an end-to-end solution. Equally, organizations that have never offered a card mailing or attaching service before can do so cost effectively, adding the functionality to their existing workflow.”

In some sectors such as retail, volumes have increased. “With this, machine speeds have had to increase. Their configurations have had to become more complex to increase the added-value and number of documents in the envelope and by matching one or multiple items of personalized and coded marketing material with the card and carrier letter. Some client requirements have also included the standard CR80 size card and the smaller key-fob size cards,” notes Jarvis.

Increased use of digital printing has also affected how mailings, attachments, and inserts are produced and handled.

Jarvis points out that with the advancing speed and print quality of digital printing as well as the reduction in cost per sheet, match and attach machines have increasingly included the printing of the carrier letter inline.

“Digital printing has become imperative because the world has shifted to mass production of products. Documents, coding, analysis, and synchronization must be the perfect match before anything begins,” says Sanchez.

Card Attachment Options

A variety of card attachment machines are on the market featuring a range of options, speeds, and finishing capabilities.

Atlantic Zeiser GmbH offers the MAILMASTER, which processes multiple small and different orders in a single production run seamlessly and without interruption. MAILMASTER starts the letter printing process in the background. It can choose from various printer trays for A4 or US letter format paper. Prior to card attaching, the printed letter is compared with the identification feature of the card using a barcode or 2D code. MAILMASTER allows attaching of up to four cards to the printed document.

Designed to run in a high-volume, 24/7 environment, Bell and Howell’s CASS C8000 is ideal for organizations that require flexibility without compromise. The high-speed secure card attachment system can process up to 8,000 cards per hour and up to four cards per document.

BlueCrest has developed a card attaching system that sits inline as an integrated element of the mail processing workflow. The BlueCrest Integrated Card Attacher offers a range of different workflow configurations that attach a variety of card types to carriers including, insurance cards, bank cards, gift cards, and drivers’ licenses. This easy-to-use system can be configured to match workflows in either an input based or tip-on configuration. It enables businesses to meet SLAs by attaching cards at speeds up to 24,000 cycles per hour, as well as add variable print, match and verify, insert, and seal—all in the same process.

“The modularity of the system eliminates the need for a fully dedicated asset. The Card Attacher can be quickly converted to run non-card applications or retrofitted to existing systems. It’s the flexibility of this swiss-army knife approach—use what you need, when it’s needed—that really appeals to print and mail business right now,” shares Edel.

CIM USA offers the CAM 8080, a solution for card matching, affixing, and mailing designed for medium- to high-volume card fulfillment applications. CAM 8080 is designed to compliment the existing CIM Pro Series line and can be set up as a standalone unit or inline with other Pro Series solutions utilizing the CIM LinkWare application.

KAS Paper Systems Ltd. is a manufacturer of envelope inserting and mailing machines including a specialist folder for folding the carrier sheet with one or more attached cards. It can supply bespoke inline match and attach and envelope inserting machines in partnership with the appropriate attaching machine provider. “Our machines are generally built to order with the required number of insert feeders and barcode reading cameras if these are specified,” shares Jarvis.

Kirk-Rudy’s 497T Servo Attaching system accurately attaches plastic cards and other products onto carriers. High-speed, accurate placement is achieved using a servo-driven friction feeder. Vertical and side-to-side adjustments of the friction feeder make setup quick and easy. Quick-setting hot melt adhesive securely holds the item in place. Run plastic cards, magnets, as well as a variety of folded paper products and apply up to three pieces onto a single carrier. If needed, the standalone feeder is easily mounted onto another product transport or web press.

Matica Technologies Corporation’s MS 1000 card mailing system is an affordable entry-level solution that can automatically read, match, insert, and seal up to 1,000 cards per hour. Simple configuration and operation of this standalone model makes for a quick and seamless integration into the existing procedures.

The MCS 1030 Base is a card attaching system featuring optional read-read, read-embossed card, and read-print functionality. It handles up to 12,000 plastic cards per hour at speeds of up to 375 feet per minute.

Pineberry offers its Card Affixer CA 10000 operating system, which Sanchez says is easy for users to handle, requiring minimal setup and changeover time. Its touch screen controls allow for easy navigation and exchange of jobs.

Step Up Mailing

Cards are popular for a range of mailed applications. With in-house capabilities, print providers meet evolving client demands. Integration and automation continue to advance in card attachment systems making them increasingly attractive to digital print environments. dps

Mar2021, DPS Magazine

card attachment, finishing