By Olivia Cahoon

Binding is essential to many print environments. In book manufacturing, it is a requirement for the production of both soft and hardcover books. When digital print technology is utilized, the model is prime for more frequent shorter runs, therefore automated binding solutions tend to simplify the process. These solutions allow book manufacturers to cost effectively produce ultra short run lengths while creating new products.

Above: Based in Landisville, PA, Yurchak Printing relies on its perfect binders from Standard Finishing for book manufacturing.

Book Manufacturing

Established in 1998, Yurchak Printing, Inc. started with five employees out of a 32,000-square foot building in Landisville, PA. It originally offered perfect bound and loose-leaf products with the goal of offering high-quality, short-run book manufacturing services to the publishing industry, manufacturing and service companies, professional associations, government agencies, and universities.

With 40 employees, the company now produces books for customers worldwide. It operates in a 60,000-square foot building and offers monochrome and color inkjet book printing services. Yurchak Printing specializes in solutions for the production of directories, periodical and journals, reference books, fine edition and illustrated books, bibles, children’s books, and university press books.

The company is composed of two business segments—print on demand and short runs. Its print on demand sector receives daily orders in quantities from one to 50 copies of multiple titles. The short-run department consists of orders from 51 to 1,500 copies, which are shipped to single or multiple locations.

Yurchak Printing also operates a full-service bindery offering EVA and PUR perfect binding, casebound books with foil stamping or printed case, saddle stitch, plastic coil, wire-o, fulfillment, mailing, and shipping capabilities.

The book manufacturer uses two digital presses. Its first press, the Ricoh InfoPrint 5000MP, is a continuous monochrome inkjet device purchased in December of 2015. “We chose this press as our entry into the inkjet printing world because of its reliability, cost, and quality,” shares John W. Yurchak, president, Yurchak Printing, Inc.

In May 2019, the book manufacturer installed a Konica Minolta AccurioJet KM-1 sheetfed press to replace its previous color toner devices. The press prints on 23×29.5-inch sheets, allowing for up to six-up letter size printing. It also produces up to 3,000 sheets per hour.

According to Yurchak, the company selected the AccurioJet for its quality, sheet size, speed, and cost. “It allowed us to stay up to date with technology and diversify into other marketplaces, allowing us to compete and stay viable.”

Yurchak Printing currently uses the AccurioJet KM-1 to print book components such as covers, dust jackets, inserts, and color coated text. “Our next step is to supplement the book components to diversify into the commercial marketplace with products such as brochures, flyers, and postcards,” shares Yurchak.

With its digital press portfolio, Yurchak Printing uses OEM ink and prints on a variety of substrates from 30# and 41# white opaque to 100# matte and gloss coated text. Covers and dust jackets are printed with 12-point C1S Coated Cover and 63# Coated Cover.

Binding Is Essential

When it comes to book finishing, digital print providers have several options.

Currently, 98 percent of Yurchak Printing’s digitally printed work requires binding. Its services include foil stamping, EVA/PUR perfect binding, casebinding, loose leaf, saddle stitch, plastic coil, and wire-o binding.

Perfect binding gathers inner pages and glues them together along the spine with the cover applied at the same time. It offers a durable, high-quality appearance but is typically more expensive. It’s also better suited for soft cover books.

Saddlestitching gathers the pages together, folds, and staples along the crease from the outside. Most saddlestitched publications are 120 pages or less due to reduced quality at higher page counts, rounding of the spine, tearing at the corners, and print gutter alignment. It’s a cost-effective solution for lighter applications such as brochures, catalogs, and newsletters.

Yurchak Printing has invested in several finishing devices, primarily from Standard Finishing Systems.

Its binding equipment includes the Standard Horizon BQ-470EVA Perfect Binder, BQ-480EVA Perfect Binder, BQ-280PUR Perfect Binder, HT1000V Three-Knife Trimmer, and the Standard Horizon Collator/Stitcher. According to Yurchak, the majority of its Standard bindery equipment was selected for reliability, quality, speed, and quick setup.

In March 2019, Yurchak Printing installed the Standard Horizon HT-1000V Three-Knife Trimmer. “We chose this machine for its variable size and thickness trimming with setup for print on demand and short-run books along with reliability, quality, and speed,” shares Yurchak.

The HT-1000V Three-Knife Trimmer operates inline with Horizon perfect binders or offline. Its heavy-duty construction allows the trimmer to run in 24/7 production with consistent high-quality finishing. The system trims up to 1,000 books of variable thickness and format sizes per hour. It handles books up to 13.39×11.81 inches.

“By reading a barcode, the trimmer automatically sets up with no human intervention,” shares Yurchak.

In addition to its Standard Finishing equipment, Yurchak Printing also uses a GP2 Casemaker, ODM Sticker and Smasher, Spiel Punch and Plastic Coil Machine, as well as various drilling, shrink wrapping, and mailing equipment.

Overcoming Challenges

For book manufacturers like Yurchak Printing, proper binding equipment is integral for cost-effective short runs. “It allows customers to print and bind in short quantities as often as needed at an economic price point to minimize the risk,” offers Yurchak.

While the company is more than satisfied with its binding equipment, challenges still exist. Yurchak Printing recently experienced challenges with static on digitally printed materials as well as difficulty adhering text to side covers.

The company overcomes these challenges by creating a humidity and temperature controlled environment, having a no-print zone on the inside printed covers, and binding with PUR glue.

Finishing Touches

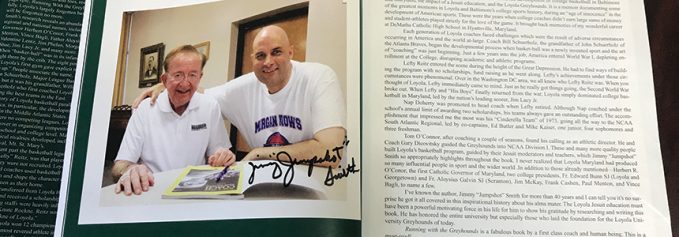

In 2019, a local author approached Yurchak Printing for a special project. Jimmy “Jumpshot” Smith, 1976 alumni of Loyola University Maryland, loved basketball and the coaches who made it possible for him to enjoy the sport. To thank his coaches, teachers, and Loyola’s Jesuit community, he decided to narrate the story of his alma mater’s basketball program.

Smith wrote Running with the Greyhounds, a 390-page epic with more than 280 photographs that depicts the story of Loyola’s forgotten basketball century. After writing the book, he requested 200 bound copies from Yurchak Printing.

Using the Konica Minolta AccurioJet KM-1, UV treated ink, and print-ready PDF workflow, the company printed the books on 80# matte text for interior text pages and 80# white opaque for four-color printed end sheets.

The books were bound on the Standard Horizon BQ-280PUR Perfect Binder. The BQ-280PUR is designed to handle the unique requirements of digital print with digital print friendly processing, quick setup and changeover, and book-of-one capability.

The device uses PUR glue, which meets the requirements of lay-flat binding for both offset and digital prints as well as coated stock. “PUR adhesive binds a solid book block with lay-flat tendencies,” shares Yurchak.

Smith’s books also feature an added level of personalization. A close associate of the author—Coach Morgan Wootten—wrote the book’s foreword. Yurchak Printing sent the printed foreword pages to Wootten for him to personally sign. He returned them and the print provider collated the signatures into the book block and bound with the text pages.

In ten working days, Yurchak Printing produced 200 copies of Smith’s book. Each book contains 390 case bound pages with a two-color foil stamped cloth cover.

“It is truly a personalized book with both the author’s and Coach Wootten’s original signatures,” comments Yurchak. “Jimmy was pleased to see his many years of research and writing come to fruition.”

Book Finishing

Print providers rely on a range of options for optimal finishing. Binding—whether stitching or perfect binding—is a critical function for many print environments. Using its Standard Finishing bindery equipment, Yurchak Printing streamlines its printing process and produces books in short runs.

Nov2019, DPS Magazine