by Cassandra Balentine

Cutsheet inkjet production presses continue to advance, complementing and competing with mature technologies like offset and toner-based production devices. While there is room for both technologies, certain considerations may sway a conversation towards inkjet.

In increasingly more scenarios, digital print providers grapple with the decision to remain a toner-based shop or invest in inkjet.

Dustin Graupman, senior director, Production Inkjet Business, Kyocera Document Solutions America, Inc., feels that advantages of inkjet include lower production costs and higher reliability. “With increased reliability, they can consider less costly and more flexible service programs. These programs meet expectations on a level far higher than the capabilities of toner.”

Glenn Toole, VP sales and marketing, MCS, agrees, noting that operating and consumable costs are known to be generally lower with cutsheet inkjet when compared to toner.

“Reliability, uptime, flexibility of substrates, and image quality are the main reasons commercial printers seek out our technology. In many cases they need to make decisions about the future of their offset presses and labor to run them and inkjet gives them the best path forward,” shares Bill Troxil, president, Industrial and Production Print, Konica Minolta Business Solutions U.S.A., Inc.

Many print production environments invest in digital inkjet technologies to solve challenges like access to skilled labor required for offset. “Inkjet digital production presses are simpler to run, require less labor, and produce less waste than the lithographic printing environment. Many print applications today involve variable data printed applications, such as direct mail, driving the demand for digital printing,” says Mark C. Little, senior director, global product marketing, RICOH Company Ltd.

Additionally, inkjet production presses that produce larger sheet sizes—like B2—are more easily incorporated into print environments that currently employ B1 or B2 offset printing. “This is resulting in a huge shift from offset to digital across the globe. Run lengths are also becoming shorter, creating an opportunity for digital production environments to be more profitable and shift to a print on demand provider resulting in growth of their business,” comments Little.

Emerging Advancements

A handful of players represent the cutsheet inkjet space. These companies continue to introduce advancements.

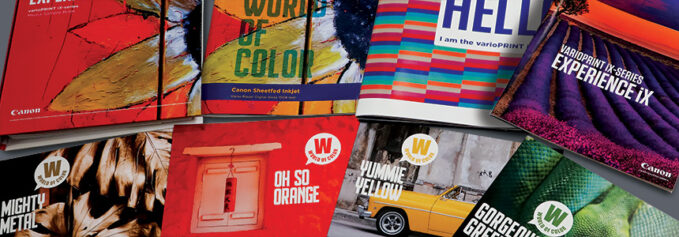

Since its launch in 2020, the Canon varioPRINT iX-series sheetfed inkjet press has established a reputation as a highly reliable, quality production printer, with 275 global orders and installations and 30 percent of all varioPRINT iX users worldwide opting for a second press or more. In line with Canon’s focus on innovation through research and development, Canon launched new software last year, enabling the varioPRINT iX2100 and iX3200 to deliver high-level performance in terms of image quality, efficiency, and productivity.

Konica Minolta continues to invest and develop its AccurioJet KM-1e HD platform. The company is on the fourth generation of the press, which gives enhanced image quality for the high-quality photo specialty marketplace. “We have also launched tools to automate maintenance routines, optimize ink consumption, monitor for conformance to G7 or other standards, and also a print quality monitoring system,” comments Troxil.

Kyocera expanded the range of media and applications, in addition to third-party finishing options for the TASKalfa Pro 15000c. It has also announced upcoming product launches, such as the FOREARTH digital textile printer and the TASKalfa Pro 55000c. “The latter targets the graphic arts as the lowest cost entry point into the market for printing direct to offset coated media with no pre-coat,” shares Graupman.

MCS distributes cutsheet inkjet technology powered by Kyocera. Toole points out that its new K146M MiCR Process Color Inkjet press offers four-color production with MiCR black for check printing and other magnetic encoding applications. “MiCR printing capability in this category of inkjet is unique.”

Landa’s digital press platform sits on top of a sturdy offset chassis built to last tens of years. “As such we are constantly improving and upgrading our digital capabilities in the field,” comments Amir Shalev, director of market development, Landa Digital Printing. “In the past year we have introduced significant improvements allowing for higher productivity, flexibility, and more applications.”

After years of development, Ricoh hits the cutsheet inkjet market with the RICOH Pro Z75. “Built on proven Ricoh technologies, this system provides high image quality of offset with the advantages of digital production. The RICOH Pro Z75 provides a capability for digital printing on B2-plus-size media capable of handling up to 400 gsm, with inline duplex printing.

The Xerox Baltoro HF Inkjet Press is the company’s flagship cutsheet production press. Billy Stojanovski, global product marketing manager, Xerox Corporation, says among the latest developments are a Videk camera integrity solution, new color profiles, coated media productivity improvements, and additional automated features to keep the press running.

Room to Grow

Inkjet technologies continue to mature. Quality and substrate compatibility have steadily improved over the past decade. However, limitations are a reality for all technologies and cutsheet inkjet is no exception.

Stojanovski points to the ability to print on synthetic or specialty stocks, thick stock, and specialty inks beyond CMYK as a continued limitation of inkjet.

Little sees speed and media as current limiting factors when compared to offset and toner production printers. “However, the market is maturing and these challenges are being solved with top-tier technologies,” he stresses.

“Substrate latitude is often the first thing customers see as a limitation,” shares Graupman. He says this is addressed with new solutions like enhanced drying capabilities and technologies that allow direct-to-gloss coated offset paper without any additional steps or special papers.

Shalev points out that direct inkjet places wet ink directly on paper, which may create unwanted interactions between paper fiber and ink. Nanography avoids these issues by placing NanoInk on a blanket, and then transferring a dry image from the blanket to the paper.

Limitations are reduced every year as cutsheet inkjet capabilities grow. “The main difference remaining between web and cutsheet presses is the production throughput,” shares Toole.

In addition, Toole admits that variable print costs may be lower with a web inkjet. However, this may not necessarily be true for the total print costs including capital costs or depreciation. “Because of this, the lower capital cost associated with cutsheet presses makes most applications attractive to print on a cutsheet device.”

Experts feel that despite progress, there are still misconceptions about today’s inkjet capabilities.

“The first misconception would be that inkjet image quality is unable to match Xerographic image quality. Now that we are there, most people think there is a single device that can do everything. There are limitations to both Xerographic and inkjet-based solutions so there is room for both,” shares Stojanovski.

If you asked the question about the limitations of inkjet a decade ago, quality would be among the top concerns. However, Graupman suggests that while quality used to be perceived as a limitation, it is rarely the case today. He stresses that as with many other print processes, cutsheet inkjet only continues to improve. “Today, there are many cutsheet and roll-fed inkjet solutions that can address just about any ink on paper quality requirement.”

Another misconception is that inkjet is reserved for very large production operations. “However, we have successfully demonstrated to many prospective customers that they can install a TASKalfa Pro 15000c next to an existing color toner device and save money by shifting as few as 200,000 pages per month from toner to inkjet,” he adds.

Application Range

The range for cutsheet inkjet is growing as quality and substrate compatibility issues wane.

The Canon varioPRINT iX is versatile and produces a number of applications from general commercial print, photo specialty, direct mail, and even transactional/statement printing. “It succeeds most in the high-volume sector of up to ten million impressions per month. iX customers run the gamut from commercial printing to book printing, direct mail, in plants, and transactional,” shares Lisa Weese, director of marketing, Canon Solutions America, Production Print Solutions.

Lance Martin, VP of marketing, Komori America and MBO America, says the Komori IS29s excels where short runs, many SKUs, fast turnarounds, and overall increased productivity and efficiency are in demand, while the Komori NS40 has the productivity and profitability needed to expand a printer’s business by meeting the growing demand for short and medium runs—including variable data printing and versioning, for an immediate turnaround on commercial and packaging work, displays, and point of purchase products.

Customers run a variety of applications on the KM-1e HD because of its sheet size, flexibility of substrates, and benchmark quality. “Applications include books and book covers, direct mail, photobooks, packaging, signage, and commercial print applications to name just a few,” notes Troxil.

By offering a highly reliable and affordable inkjet press, Graupman says Kyocera has opened a variety of opportunities that were not previously been explored. “The TASKalfa Pro 15000c is the bridge between EP devices and high-end, high acquisition roll-fed devices,” he states.

MCS’s MiCR press is ideal for check printing, including business, personal, and payroll check printing, says Toole, especially in instances where four color is required and the entire printed piece can be completed in one-pass without the need for printing shells and running pre-print through a B&W toner system.

All of the MCS K146 presses are well suited for marketing and transactional applications on uncoated materials. “The high-volume duty cycle and cutsheet workflow make them ideal for long runs, short runs, and reprints. In both instances, the extremely low cost of the print, durability, and simple workflow sets these presses apart,” adds Toole.

All general print and packaging applications requiring extremely high-quality and industrial-level productivity, to 32 pt stock, including in-store, pharma, variable, security, are well suited for Landa Digital Printing S10 and S10P products, notes Shalev. “A single Landa printing press can move from B1 posters to thick folding cartons and on to coffee table books and art canvases that ‘wow’ with color—and still, our customers have barely scratched the surface of what is possible.”

Stojanovski points out that the Baltoro excels in transactional applications, direct mail, marketing collateral, postcards, books, and magazines with its differentiator being tabs.

Market Demands

Print providers seeking to invest in inkjet prioritize higher uptime and easy maintenance. Improvements in quality and media compatibility continue to grow, making cutsheet inkjet technologies widely accepted for more applications.

Mar2024, DPS Magazine