By Melissa Donovan

There is always room for improvement and workflow solutions are no exception. As digital and hybrid label printing undergo further advancements, leading and on-trend technology like artificial intelligence (AI) will play a key role. Ultimately, the newest workflow solutions enable label converters and print providers to grow or maintain business at high levels of efficiency.

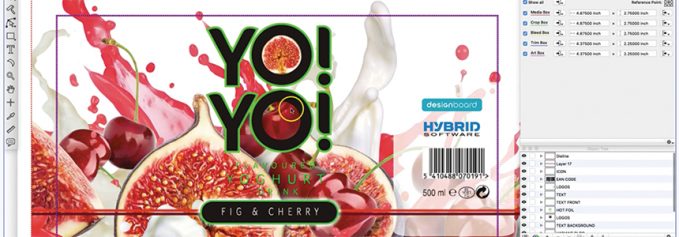

Above: Label Traxx integration with HYBRID software’s CloudFlow workflow can automate prepress.

Workflow solutions for digital and hybrid label production continue to advance. The evolution of these tools presents print providers and label converters with accessibility to features such as order processing, production planning, shipping, and reporting—all in one package.

Correct Use

Label printers are aware of the available workflow solutions for digital or hybrid label printing operations. Most of them actually implement these in their production facilities. However, many are not fully taking advantage of the tools available.

Of the range of industries that utilize digital printing capabilities, James Nelson, global product marketing manager, packaging, EFI, says that the label industry is a little more advanced compared to other packaging producers. This is because “it is highly competitive, often short order volumes, and usually a higher number of SKUs so maintaining cost effectiveness through efficiently utilizing workflow tools becomes increasingly important.”

While print providers and label converters are more advanced when it comes to using workflow solutions, João Pereira, label converting and flexible packaging department consultant, Sistrade, shares that, “the main deficiency when it comes to their use is that most of the companies use generic, separate tools for various operations and departments instead of having the entire business and production area covered by one solution.”

“They key is to have an integrated system that can do it all. Essentially one where you can enter information once, copy it, and validate the information in real time all the way through the process. If you have separate systems, you end up with a lot of duplication and rekeying of data,” notes Gerald Clement, partner, Computer Productivity Services, Inc. (CPS).

For those implementing workflow solutions, there is always room for improvement. “Printers should constantly evaluate where they see bottlenecks in their production and sales processes. You must be able to measure what you seek to improve—what gets measured gets done,” advises Dorothy Asboth, North American sales manager, Label Traxx.

“The challenge with leveraging software workflow tools is recognizing that it potentially takes away work from human beings and print providers are sometimes reluctant to continue to evolve with their workflow tools, and get stuck in a rut to implement them,” admits Graham Blanks, director of business operations, North America, Dalim Software.

Record Achievement

Common workflow goals that label users hope to achieve include automation, efficiency, and minimizing error—all of which can lead to a higher profit margin when combined.

“Workflow tools are technology tools that reduce the amount of time taken in tasks, and reduce the number of touches. The goal is to automate as much of the workflow as possible while at the same time simplifying it so a user can have quick access to instantly understandable data,” explains Jack J. Lafler, VP of sales and technology, HiFlow Solutions.

Efficiency is essential, especially in scenarios like the ones many print providers and label converters encountered at the onset of the COVID-19 pandemic. “Standardizing processes and offloading tasks to automated workflow software significantly increases efficiency and throughput, while the integrated systems enable a business to handle 40 percent more jobs without the need for additional headcount. At the early stages of the pandemic, the ability of converters to handle an increased volume of orders while also meeting the ever-shortening turnaround time demands proved crucial to the continuation of customer relationships,” says Jan De Roeck, director industry relations and strategic marketing, Esko.

A workflow solution should provide a bird’s eye view of the goings on on a shop floor. “Without knowing the reality of the production area, it is almost impossible to provide quick and precise estimates or correctly manage warehouse and procurement processes. Therefore, workflow tools should serve the managers as a compass for quick decision making,” shares Pereira.

When used correctly, workflow solutions allow businesses to “redeploy resources in key areas and build in a level of contingency and repeatability to the way they operate as they transition to a more digitized, automated operating model,” comments Nelson.

Top Features

Digital and hybrid printers and label converters look at a number of features in their workflow solutions to get the job done efficiently. Basic needs include estimating, order processing, ticketing, stock management, production planning, shipping, billing, and reporting. Some of the most requested features impact customer ordering processes and how they view the print job in the production process in real time.

Estimating is a top tool. “This is quite natural, since the fierce competition on the market requires speed, quality, and low price,” notes Pereira. Efficient stock management, production planning, and reporting are equally important, he adds.

Lafler seconds Pereira’s statement about estimating. “One of the most asked about features is how our estimating system uses custom templates to speed up the process from quote to job ticket.”

“We always hear that people want a faster, easier, and more accurate estimate template. Based on the history of work that has been printed before, they want effective production planning—ways to utilize presses most efficiently. People always like the digitization of job tracking to easily see where jobs are in the production process,” explains Mike Agness, EVP, Americas, Hybrid Software.

Asboth believes some of the most utilized features focus on customer acquisition processes. “There has been a jump in interest in online portals for customers since the start of the pandemic. Companies look for ways to make it easier for customers to work with them in contrast to what their competition offers. Saving time for your customer can also result in lowering your internal costs to process those orders.”

Print buyers’ demands drive new feature sets. “For example, they want to log into the print provider’s website, get an estimate, and view the production process. They also want to quickly and easily approve labels for production. A workflow solution could provide a storefront with a view to lights-out production. Now, customers are closer to the print process than they have ever been,” says Blanks.

“By streamlining the order entry and quoting process, companies are able to win more business as well as improve the core order to cash timelines. More recently, customer collaboration or ecommerce portals have been a significant step forward in improving customer relationships by offering upstream visibility in real time of job or order status within the plant. Customers can manage their own inventory and improve their strategic planning around promotional or seasonal packaging,” agrees Nelson.

The Smart Factory

AI continues to expand into all facets of our everyday life. On the print production floor, expect to see AI used with the intention of enhancing the efficiency of workflow solutions even further.

It’s only natural that AI will be used in label printing, points out Pereira. “As the data flows increase and their swift treatment goes beyond human capabilities, the need to allow machines to perform automated reasoning tasks with ever-increasing complexity is growing day by day.”

Asboth says label printers are starting to see more orders that are smaller in total size but have many versions—so more data. “They have gone from dozens of jobs per day to hundreds of jobs per day. It forces printers to choose first in, first out scheduling rather than cost-effective scheduling. AI can use historical data to create the most efficient schedule and view alternate schedules. The printer can define key parameters to follow—key customer or operator availability—to create realistic schedules.”

What is relevant to label printers is that AI can detect possible errors in the production workflow before production even starts. “Also, as a job is created in estimating, the AI can detect errors here. AI has the ability to learn the most efficient ways to construct a workflow based on previous runs,” comments Lafler.

While analyzing documents and extracting information about them is where AI is currently utilized, Blanks sees it going further with the opportunity to help predict or flag issues.

“Predictive analytics that can look at customer order patterns and adjust material quantity, automatically create orders, and adjust machine schedules or run lengths in real time will be exciting to witness as the industry further develops,” agrees Nelson.

Agness also believes that in the future, AI will track repetitive work and learn how to produce it better and faster for the next job request.

Options for the User

Here are some vendors’ workflow solutions tailored toward label converters and print providers.

CPS Print Management is powered by Microsoft Dynamics G. The solution includes a quick quote to invoice cycle, easy shop floor control, fast sales order processing, a highly scalable system, and low total cost of ownership for systems with 25 to 100 users. The company specializes in ERP systems for narrow and wide web converters with between 25 to 100 concurrent users.

Dalim ES is a web-based solution that makes it easy to manage packaging though a single online platform. It helps quickly and efficiently validate the creative and technical production of packaging, while organizing the content within a digital asset manager. A primary feature of Dalim ES is its ability to simultaneously manage labels and packaging as well as other marketing projects.

EFI Radius is an ERP platform equipped with highly tuned capabilities for label production that have been developed over many years. Part of the Packaging Suite, which is modular by design, it works well with value-added applications like Market Direct for storefront creation, the iQuote visual estimating module, and the dynamic rules-based scheduling solution PrintFlow.

Esko WebCenter for Labels is a packaging management solution that helps tackle the demands label converters and print providers face daily, like more jobs with shorter run lengths and fast turnaround times. The system guides and standardizes order handling and streamlines approval communication between a business and its customers. All exchanges are systematically tracked and risks flagged ahead of time.

HiFlow offers several solutions designed for label printers. Tool and die libraries track anilox rollers, rotary dies, and any tool needed for a specific production run. If the tool in the run is a common tool, like a rotary die, the system stores how many impressions exist on the tool and the number of impressions before it needs resharpening as part of the report. The workflow diagram shows every step of a label job from start to finish—materials, tools, processes, and machines necessary to complete the run and their availability.

Hybrid’s CloudFlow is a web-based, modular production workflow suite for file processing, asset management, soft proofing, and workflow automation. It is tailored for label graphics with support for PDF, color separation, trapping, screening, and proofing. CloudFlow connects to surrounding IT equipment and databases to retrieve parameters and other production instructions to automate production and eliminate double entry.

The Label Traxx platform is developed around the workflows of narrow web label converters. It supports digital printing through partnerships with key players in the space. As the narrow web converter expands its mix to include shrink wrap and flexible packaging, The company modified its system to support the multiple step processes common with these products.

Sistrade’s fully integrated solution is designed from scratch for label converting companies. Highlights include estimating and an increased emphasis on the technical definition of the product through data sheets. The solution covers the entire production lifecycle from job order preparation to shop floor control and shipment preparation.

Efficiency and Productivity

While many print providers and label converters currently utilize workflow solutions, they may not be leveraging them to their utmost capabilities. Perhaps the biggest challenge is a lack of integration, which could lead to improved efficiencies and productivity in label production environments when properly utilized.

Estimation tools and customer-related processes like online portals and tracking jobs in real time give print buyers more power and confidence throughout the process.

AI’s influence on workflow tools is growing as more utilize this technology to analyze documents, extract important information, and leverage it to their benefit. The future looks bright as AI is poised to further influence workflow in the area of predictive analytics. This circles back to helping achieve ultimate goals of efficiency and productivity. dps

Mar2021, DPS Magazine