by Melissa Donovan

Packaging continues its transition to digital print and workflow software adapts in response. Digital and hybrid print environments take advantage of emerging solutions that touch every facet of the package production process. Areas of note are project management, digital proofing, and digital asset management (DAM). A modern digital packaging environment implements all three functions to achieve efficiency, improve time to market, and decrease costs.

All Together Now

Advancements in technology allow project management, digital proofing, and DAM to be integrated into one solution versus stitching separate systems together.

Bringing all three functions into one solution offers significant advantages in packaging, according to Gemma Wood, Smartflow product manager, Loftware. “Firstly, it streamlines the entire packaging production process by eliminating the need for manual handoffs and data transfers between different systems. This integration ensures seamless communication and collaboration between teams, thereby reducing errors and delays,” she notes.

Wood also believes “an integrated solution provides a centralized repository for all packaging-related data, including project timelines, artwork files, and digital assets. This centralized approach improves visibility, accessibility, and version control, enabling efficient project management and ensuring everyone works with the most up-to-date assets.”

“Combining project management with digital proofing and DAM in one solution enables small teams and growing businesses to increase speed and simplify their go-to-market processes,” explains Adrian Fernandez, GM, Mox. “This rapidly reduces approval time for impactful product packaging and content, enabling teams to develop and deliver artwork and content to get new SKUs to market quickly, efficiently, and in compliance with all regulation requirements.”

Integration equals consistency. “As digital print becomes more popular, more brands integrate these three areas. The primary reason is to maintain a consistent brand appearance in their campaigns across regional, national, and/or global markets,” explains Mark Geeves, director of sales and marketing, Color-Logic Inc.

A workflow that consists of all of these functions—project management, digital proofing, and DAM—within a single solution has many advantages, says Guido Haeussler, sales manager packaging printing, ColorGATE. Whenever new software is implemented, the team must learn how to work with it. Interfaces are developed so that different software can talk to each other. It is important that all these pieces are able to work together and that no data is lost in the process.

“When you reduce this to one software, there are none of these problems,” offers Haeussler.

Mike Agness, EVP, Americas, HYBRID Software, believes there are advantages to integrated solutions as well as separate systems. “When they are integrated, you expect that the software works seamlessly together. You can also call one vendor to provide service for all the pieces if something goes wrong.”

Conversely, “if a complete system is provided by different applications, it’s usually because one of the pieces is more complete, fits your needs a bit better, has already been purchased, or offers some functionality that you cannot get from anyone else,” adds Agness.

The size and scope of the production house is a great determining factor for whether integration or stitched together systems are preferred. “Small to medium printers often prefer a single application because it is easier to deploy and offers seamless service and support when there is a smaller IT department,” states Graham Blanks, director business operations NA, DALIM SOFTWARE.

Larger companies with larger IT departments tend to be more comfortable integrating different applications. “They have no problem sourcing applications from separate vendors. It truly becomes a business decision to determine if a company has the resources to manage either option. The connection between all of these appear seamless but the user experience is different between the applications,” continues Blanks.

Determining Relevancy

Modern digital packaging production—whether solely digital or a hybrid environment—thrives with key functions including project management, digital proofing, and DAM.

Agness says all three functions are critical in assuring the fast processing of jobs and files.

“Many businesses and brand teams still rely on emails with file attachments, spreadsheets, and shared drives for workflow management and collaboration. In today’s omnichannel environment, this is simply no longer fit for purpose. It’s easy to lose track of digital assets and teams’ input, especially for approvals, feedback, and version histories. If the final content is incorrect or the wrong version is used at the wrong stage of the go-to-market process, brand reputation is at risk,” notes Fernandez.

Use of project management, digital proofing, and DAM allows printers to meet the advantages of digital printing including personalization, localization, and time to market, according to Geeves.

“These features help speed and simplify your go-to-market processes, especially in complex packaging print environments. There is a need for increased automation, also to save costs and resources,” notes Haeussler.

Specifically in reference to project management, this function is essential to modern digital packaging production for a few reasons. “It offers three important functions—knowing what and how to produce, and when and how to produce it. It also provides a foundation for reviews and approvals,” shares Agness.

“Project management tools enable effective planning, resource allocation, and collaboration among teams, ensuring projects stay on schedule and within budget. They help streamline complex workflows, manage dependencies, and track progress, resulting in improved efficiency and timely delivery of packaging projects,” explains Wood.

Without project management—there is chaos, warns Blanks. “What is required with any project is a single course of truth for each job or product in the organization. It is better to have a central source of information rather than relying on email messages or phone calls to confirm changes.”

Digital proofing is also important because “it provides a means to allow customers to review and approve both content and color. They also keep a record of who approved each and every project, which is important if issues arise with the final product,” says Agness.

“Digital proofing plays a vital role in the packaging industry by facilitating the review and approval process. With the ability to annotate and comment directly on digital proofs in real-time, stakeholders can provide clear and speedy feedback to ensure accuracy, consistency, and compliance with brand guidelines. This collaborative approach eliminates the need for physical proofs, which reduces costs and speeds up the review cycle,” adds Wood.

DAM is critical in terms of content, making it both available and easily accessible, notes Agness. He adds that it is also important in regards to reprints and processing them quickly.

“DAM systems are essential for organizing, storing, and retrieving digital assets used in packaging production. They provide a secure and centralized repository for artwork files, images, logos, and other digital assets, ensuring version control, easy retrieval, and efficient reuse. DAM systems enable seamless collaboration, improve asset traceability, and enhance brand consistency across packaging projects,” says Wood.

Evolving Tools

The latest demands in packaging—including the increased use of digital—have pushed project management, digital proofing, and DAM to evolve.

“Overall, these tools have embraced digital transformation and advanced functionalities to meet the demands of modern digital packaging production,” shares Wood.

Two drivers are responsible for this, according to Blanks. “The first is a movement from traditional communication channels to a multitude of faster digital communication channels. The second is tying the brand owner much closer to the creative operations and the production people who are charged to create and produce the final artwork for digital print.”

Packaging—and marketing—is becoming more complex, and this is also why tools must evolve to standardize and simplify the process. “As a business scales up, there are many different levels to consider. Launch dates might vary in different markets, product shelf life, logistics—all of these can play a part in deciding path to market,” shares Fernandez.

“We continue to receive feedback from customers and partners about the need for higher levels of automation with minimal operator intervention. Automating processes is increasingly necessary to keep up with customer demands for customization and short production times,” adds Haeussler.

Today’s project management tools provide enhanced data speeds between management information systems (MIS)/enterprise resource planning (ERP) and production systems. Digital proofing offers capabilities like ensuring the right person has reviewed and approved the order. DAM offers faster access to content, simultaneously making that content easier to locate, according to Agness.

Wood elaborates on the integration of digital proofing and DAM. “Digital proofing tools have evolved to support sophisticated annotation capabilities, enabling stakeholders to provide detailed feedback directly on digital proofs. They often offer advanced comparison features, allowing users to compare versions or variants of packaging designs visually. DAM systems have adapted to handle a range of file formats and support version control, metadata management, and robust search capabilities. They are more intuitive, allowing users to preview assets and perform quick edits within the DAM interface.”

Cloud Popularity

With more data placed in the cloud, it only makes sense that workflow systems continue to move in this direction. With packaging in particular, project management, digital proofing, and DAM are all functions that will eventually be located in the cloud.

“Cloud-based solutions will continue to grow in popularity for pretty much all applications. Although on-premises and cloud-based options typically provide equal functionality, using SaaS services reduces the required IT infrastructure for the customer. You are also assured of immediate, up-to-date upgrades to software,” shares Agness.

Specifically to packaging applications, cloud-based workflow systems are predicted to become more popular for project management, digital proofing, and DAM, says Wood. “Cloud-based solutions offer numerous advantages over on-premises systems. Firstly, they provide scalability, allowing businesses to easily adapt to changing workloads and scale up or down as needed. Cloud-based systems also offer high availability, ensuring continuous access to critical data and applications.”

While Haeussler agrees that cloud solutions are advantageous, they make things more challenging when “large amounts of data are involved or when users are skeptical about moving production-critical infrastructure to the Internet. Core RIP and color management for high-quality requirements may take some time to move to the cloud. In the meantime, it may make more sense to design them as centralized workflow components that remain on-premises.”

“Actually, in the true sense, whether or not a print provider is hosting a system on their own, or via SaaS through a data center, it is ultimately a cloud-based system. The truth is, the brand owner sees the application in the cloud. As soon as you deliver a production system or access content on the web, you are a cloud service provider. Applications are generally web/browser-based, so they see pretty much any system through the cloud,” admits Blanks.

Workflow Options

Vendors interviewed for this article shared their products with us and whether or not they offer project management, digital proofing, and DAM tools.

The Color-Logic system for metallic colors and print embellishment is unique. Color-Logic creates all special effects at the design stage, based on its profile of each individual printing press and the precise process being used. The PDFs generated make Color-Logic compatible with most print systems.

With a web-to-production solution, ColorGATE handles the entire production workflow, from online ordering to logistics. Custom Create covers the entire process from ecommerce to final production, including all the benefits of project management, digital proofing, and DAM solutions. A software solution that is compatible with ecommerce systems, it manages every step from order to final production, is easy to use and, together with the company’s REST API support, can easily integrate into existing processes.

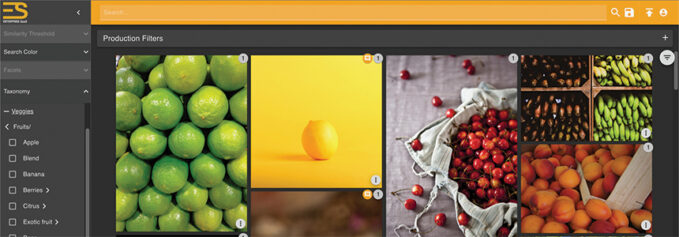

DALIM ES is a complete, but modular system offering project management, online digital proofing, and DAM. One strength of DALIM ES is its project management. DALIM ES provides a clear view of marketing workflow milestones and approval processes, revealing potential barriers at an early stage. Users create highly efficient workflows that speed up approval cycles with DALIM ES online proofing. Working from a browser-based system, change requests can be viewed on a collaborative basis, in real time. DALIM ES offers a DAM for all media content, integrated with production and approval cycle tools.

Earlier this year, Esko launched Mox to help growing brands and small businesses bring quality products to market in a consistent, fast, and sustainable way. It combines project management, digital proofing, and DAM in single, cloud-based product content tool. Offerings include collaboration, review and approval, workflow templates, tracking and auditing, advanced proofing, and DAM.

HYBRID CLOUDFLOW addresses project management, digital proofing, and DAM through various modules. HYBRID DATALINK is responsible for connectivity and data collection from MIS/ERP and other data sources. HYBRID WORKSPACE keeps a central database for all CLOUDFLOW applications, and offers file and asset management. HYBRID PROOFSCOPE is a turnkey solution for soft proofing and collaboration. HYBRID JOBS offers job management by presenting it in a graphical user interface.

A configurable and automated artwork management platform, Loftware’s Smartflow is an SaaS that eliminates manual processes and paper files by making all content accessible in the cloud. It streamlines the packaging concept-to-shelf process with customized workflows to gain efficiency and virtually eliminate manual mistakes. With improved visibility on all steps of a project, Smartflow enhances stakeholder collaboration through online proofing and ensures accountability with time-sensitive task reminders. Smartflow also offers version control, centralized content management, and online proofing and comparison tools to help ensure control and compliance.

Functional Processes

Project management, digital proofing, and DAM are three areas of the digital packaging workflow that thrive when working together, but can also perform well on their own. Automation of each tool’s functionality is important to modern digital packaging production, especially as packaging becomes more complex in design variability and the modern workspace means communicating with people both at a desk and a country over. These systems offer a streamlined process for both digital and hybrid packaging environments.

Nov2023, DPS Magazine