by Cassandra Balentine

Print embellishment is attractive to print providers looking to reign in luxury clients. In addition to digital embellishment systems, businesses add protection and pizazz with coating and laminating.

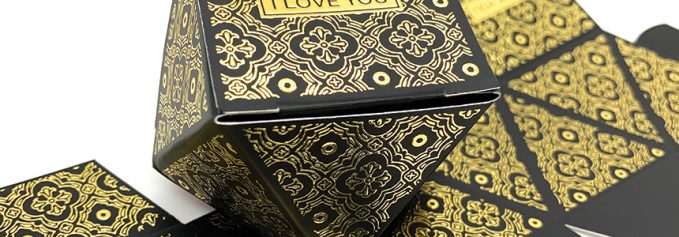

Above: Duplo offers a solution for laminating and foiling. The DFL-500 Dry Coat/Foil/Laminator allows users to laminate and foil on the same machine.

Laminates and coatings are designed to protect, preserve, and enhance output. Print buyers demand a variety of effects that are possible with coating and laminating systems, including tear-resistant, holographic, biodegradable, and antimicrobial properties as well as UV spot coating, gloss and matte, and security features.

As print embellishment becomes more mainstream, print consumers have seen and handled embellished products and don’t want any less for their prints. “More budget is being allocated for shorter runs, allowing the print provider to add real value to make an impactful finished product,” offers Brad Drever, managing director, Skandacor.

When it comes to finishing digitally printed output, print providers continuously search for new technologies and ways to differentiate themselves, says Anthony Gandara, product manager, Duplo USA.

New Trends

Several trends surround coating and lamination in the digital print space including a demand for tactile effects, security features, and antimicrobial films and coatings.

A printed piece that offers a unique look and feel helps draw attention. William Gaspelin, VP, fuseFX, a Databind Company, believes that anything laminated tends to be held onto longer by the recipient of the printed document, meaning advertising pieces get noticed more often since they are not immediately thrown away.

“Demand for value-add sensory effects and performance-enhancing characteristics are trending heavily in the world of film coatings,” shares Dragan Nikolic, business development manager, Nobelus. “Soft-touch laminate continues to blaze trails farther into multiple segments of packaging and commercial print due to its ability to elevate every print consumer experience it touches. Performance films are rapidly fulfilling newer demands for sustainability, safety, and security.”

Tactile films are also popular, including soft mattes with a velvety look and feel. This film is often combined with UV spot coating. “A gloss spot coating on top of a soft feel matte can create a unique look and draw attention to a specific portion of the print,” shares Gaspelin.

Drever sees two major trends in lamination films. The first is for pre-embossed tactile films and the second is the use of lamination films as a component of the embellishment process, not as a final finish itself. “This has caused us to work to develop laminate films with special top coatings that can accept spot UV, foils, and digital toner. When combined with the tactile effects of the laminate film, amazing results are realized,” shares Drever.

Further, encapsulating a printed piece with a full border of lamination film on the document will make it resistant to moisture. “This allows documents such as menus to be sterilized by wiping it down with a cleansing wipe, an important thing during a pandemic,” comments Gaspelin.

The pandemic has also created increased interest in films with antimicrobial surfaces. “These types of films can eradicate viruses and bacteria on the surface,” points out Gaspelin. Typically the antimicrobial is a coated surface on the film. “This coating increases the cost of the film, but for the right application, the cost is well worth the protection,” he offers.

Oran Gilmore, director of sales and business development, Autobond Laminating, Inkjet Spot UV, and Foiling Machinery, notes major developments in digital printing from the inks used to an evolution of maximum format increases from 13×19 inches to larger digital presses up to 20.75×29.5 inches. “Press productivity is also considerably faster. On the lamination side, we’ve seen increasing diversity of available films. It has expanded from gloss and matte to soft touch laminates, holographic films, metallic, gritty, high gloss, and a plethora of other specialty films now available to add perceived value,” he offers.

The process of performing lamination is also leaning towards more automation. “Machines that automatically feed, laminate, and cut finished sheets are highly desired as they eliminate manual labor that is time consuming and costly. In fact, automated laminating systems typically pay for themselves in about a year in labor savings alone,” adds Gaspelin.

Pushing Forward

Several market drivers lead to increased demand and new trends in coating and laminating digitally printed output.

Nikolic says regional brands are competing with global brands. “Today, small- and medium-sized businesses have more access to higher end print enhancement and embellishment options thanks to print providers with more digital print and value-add finishing services under one roof. This helps level the playing field against huge marketing budgets from larger corporations and allows boutique brands to differentiate by providing more memorable experiences via haptics or other special effects to attract new customers.”

As for the effects of global current events, Nikolic says online ordering has skyrocketed but so has counterfeiting. “The need for brand identity and authenticity exposes a new purpose for embellishments and sensory enhancements. Also, as restaurants and schools re-open across the globe, antibacterial film will help mitigate bacteria transmission on menus, children’s books, and other high-touch print materials,” shares Nikolic.

Sustainability also drives innovation. “We are discovering films can play a role in plastic reduction demands made against rigid plastic consumer packaging. We anticipate that bio-based film will draw much interest from the label and flexible packaging segments,” shares Nikolic.

The need for high-quality, quick-turn print is driving substantial growth in the digital sector of the print market. Gilmore comments that print quality has become outstanding on many of today’s digital presses. “The market is therefore demanding digital presses deliver the benefit of digital print, such as quick makeready and variable data support with higher productivity, larger formats, and print quality that were once only associated with offset presses.”

Drever points out that what would traditionally be UV coated may now be laminated so further embellishments like spot UV or foil can be applied to it. He says foil on top of and under spot UV is now an expected offering.

Adding Value

Spot UV coating is a popular effect utilized by digital print providers. As previously mentioned, digitally printed sheets are often first laminated to ensure an optimal surface for UV coatings. This also adds a superior look and feel.

Gandara points out that in most cases, printers looking to add spot UV to their digital print services are initially looking for something to help them differentiate themselves from the competition. “But spot UV offers much more than that; it adds value to digital print output. Spot UV creates differentiation and increases the value of digital print output by adding another dimension that the consumer can actually see and feel. As a result, it can be used to attract new business, retain existing customers, and most importantly, generate higher profits for digital output. Whereas, digital print by itself generates little to no profit,” adds Gandara.

Gilmore believes printers are on the lookout for ways to add perceived value to their products and make their print stand out, whether it be a book cover on a shelf, high-end packaging that reflects quality of product inside, or marketing materials that reflect brand quality, the end customer wants to improve perceived value for their products and their brand. “Spot UV, especially when applied over a high-end laminate such as soft touch, exudes quality and increases perceived value of the printed product. Further, many printers have run traditional screenpress equipment or sent out to finishers running traditional screenpress equipment. In either case, screen making and makeready times associated with screen technology increase cost. Especially for digital printers it does not fit with their print-on-demand business model.

Therefore, there is an increased demand for inkjet spot UV coating/digital embellishment machinery in the digital market.”

Cost is always a consideration, including the initial capital investment of the equipment as well as the cost of consumables. Consumable cost is typically passed down to the customer. “If properly implemented, marketed, and sold effectively, spot UV can be a profit generator,” shares Gandara.

Gilmore agrees, noting that added cost primarily comes down to the varnish, capital expenditure, and labor producing the work in house. “With that said, the savings of producing the work in house delivers a quick return on investment (ROI) for those currently sending it out. Further, users gain control of quality and turn time. Most digital print shops could not afford the time to send this work outside, so the technology opens this market.”

Nikolic feels that not adding value-add film coatings can be far costlier to a brand than calculating in a few extra pennies per sheet or linear foot on a web. “The landscape is too competitive to dismiss the value of sensory marketing. We find the ROI to the brand is immediate, and the converter a close runner-up. If converters decide they want to reject commoditization and serve in vogue brands, they must bring in the technology and material in house to do so effectively.”

Design Thoughts

When adding laminates and spot UV coating, design should be considered at the forefront. Factors that come into play include paper and substrate selection, registration, varnish thickness, and image quality.

Spot UV coatings are a design-driven technology. “To make the most of the technology, it is best to have a graphic designer. They can help create amazing effects and texture. The possibilities are almost limitless,” notes Gandara.

UV spot coatings on inkjet output look superior when printed over a laminate, according to Gilmore. He says at a functional level it eliminates the variability of inks, coatings, paper, dyne level, and other factors that may impact print quality of inkjet UV inks and provides a nice printable surface. “Inkjet spot UV can only be run with gloss UV, as opposed to matte or specialty UV varnishes with glitter, this understanding is crucial at design level,” he asserts.

“Designers working with spot UV need to take that into consideration at the start of the creative process, as it can be used as an integral part of the message and not just a finish that goes on top. Whether that be a decorative pattern or overlay, or actually part of the message, it needs to be incorporated as multiple layers into the file,” shares Drever.

Coating Challenges

Laminating and coating digitally printed output is a straightforward process with limited challenges. Paper and substrates, registration, varnish thickness, and adhesion are factors to consider.

“These things are easy to implement, manage, and control during the designing process. Since spot UV is a digital inkjet process, it is easy to test and make changes very quickly,” offers Gandara.

One thing to consider is the dyne level of a surface. “An appropriate and stable dyne level on a treated modern film will eliminate some common compatibility challenges with substrates,” offers Nikolic.

When UV spot coating is applied on top of a lamination film, it is important that the lamination film surface has a high dyne level—above 42 dynes—to get adhesion of the spot coat to the film surface, explains Gaspelin. Soft feel matte films have a high dyne level as the surface is actually a coated matte with a high surface energy that is excellent to combine with spot UV coating.

Laminating films used on digitally printed sheets typically require specialized adhesive layers to ensure bonds to the print that have fuser oils present from the digital printing process. “It is important to inform your laminating film supplier what digital print engine is being used to print with as to ensure the laminating film will not have adhesion issues. He explains that some digital print engines lay down more fuser oils than others, and systems like HP Indigo do not use fuser oils at all. “Knowing what digital print engine is used can ensure best results when laminating,” offers Gaspelin.

Gilmore points out that if the print comes off of a toner-based digital press it can cause reticulation of the printed spot UV image, and/or issues with adhesion when attempting to apply direct to the substrate. “Apart from improved look and feel of the product, adding laminate eliminates issues associated with direct application of spot UV varnishes onto toner-based print.”

“Soft touch lamination has a specific surface tension that the spot UV can bond to, as well as solve issues with edge resolution bleeding out on top of the toner. It also provides a nice matte background to the gloss UV for ultimate contrast,” adds Drever.

Another issue with spot UV is ghosting, where you can see the outline of the application on the backside of the sheet, making it unsuitable for duplex printed pieces.

“From the laminate perspective, there are surface tension values that must match the compatibility of the polymer,” says Nikolic. Laminate provides a very stable surface for spot UV, which makes it easier than guessing what paper-based or synthetic substrates are compatible.

Next-Level Appeal

Print buyers are looking for value-added, digitally printed output. Print providers can achieve this with the use of coatings and laminates, often paired together for optimal results.

Oct2021, DPS Magazine