By Melissa Donovan

While inkjet holds a significant presence in the market, electrophotographic (EP) presses—both dry and liquid (LEP) formulations—remain prevalent. The devices’ capabilities are part of the attraction. Media compatibility, advanced inks and toners, finishing techniques, and fifth imaging stations present a broad range of application options. While direct mail, posters, photo books, and invitations—to note a few—are common applications, these presses are making their way into one of the segments rapidly affected by digital print—packaging.

A recent study, Digital Printing for Packaging Market: Global Industry Analysis and Opportunity Assessment, 2017 –2027 by Future Market Insights (FMI) segments the packaging market by technology—liquid toner EP, nano-graphic printing, inkjet technology, and other. According to the firm’s findings, liquid toner EP is the largest segment, accounting for over half of the revenue share by technology type. In terms of revenues, this segment was valued at just over $6B U.S. in 2016. FMI projects it to grow at a 16.6 percent compound annual growth rate (CAGR) and surpass $32B U.S. in revenues by 2027.

In the report, FMI refers to packaging as including the following product types—labels, films and wraps, bags and sacks, boxes, folding cartons, bottles, cans, pouches, and sachets. Of these, labels is the largest segment, accounting for over $7B U.S. in revenues in 2016. FMI estimates demand for labels to increase at a 16.7 percent CAGR to reach $38.44B U.S. in revenues.

These statistics illustrate the wealth of opportunity available to those running EP and LEP presses. In addition to traditional commercial applications, these capabilities are poised to take advantage of some of the hottest trends on the market while simultaneously stand at the forefront of a new service offering.

Critical and Unaffected

EP and LEP presses continue to evolve despite the competition from inkjet. Critical feature sets found on these devices include media compatibility, finishing techniques, and special colors. They remain unaffected by inkjet.

Compared to inkjet, EP is compatible with a larger variety of substrates. “While paper mills have made great progress on producing papers more suitable for inkjet printing—as have ink, printhead, and press manufacturers—there is still a need in many cases to use treated or special substrates, which are more expensive than standard offset papers. With EP, substrates are not an issue,” explains Danny Mertens, corporate communications manager digital print solutions, Xeikon, a division of Flint Group.

In particular, Mertens points to Xeikon’s EP presses and the toner’s low-fusing temperatures, which allow for printing onto a variety of substrates that normally would have difficulty running on high-fusing temperature toners. “There is no need for special substrates or coatings. Presses can use substrates ranging from very low 40 to 350 gsm,” he continues.

For example, the Xeikon 9600 prints to coated and uncoated paper, paperboard, synthetic substrates, and label stock. Designed to complement the Xeikon 9000 series, it is a new generation entry-level press that prints 5/5 one-pass duplex at up to 21.5 meters per minute or 70 feet per minute at a high resolution of 1,200 dpi.

While aqueous and UV inkjet particularly still have issues with food safety and eco-friendly status, toners are already qualified for use by many manufacturers. Xeikon toners are food safe and can be used on labels and packaging for direct and indirect contact with food and other sensitive materials.

Inline finishing is a key differentiator, according to Bill Bay, manager, Xerox Developed Products Business Team, Xerox Corporation. “Many providers of short-run digital print prefer to have their jobs finished inline, rather than having to move to an offline bindery.” Every Xerox EP press offers a range of flexible, efficient inline finishing options to produce everything from stapled sets to lay flat books and full-bleed saddle-stitched booklets.

Xerox recently launched a new family of EP presses, the Xerox Versant 180 and Versant 3100 Press, which include integrated finishing solutions.

While production inkjet is constrained to CMYK in many presses, most EP devices offer a fifth channel or station that can run specialty colors like white, orange, green, clear, metallic, or fluorescent. In many cases these can be used to enhance the color gamut or as a spot color, adding pop to a printed piece.

“Control of color saturation at production speeds is also a key advantage, as is the ability to include the fifth station ink capabilities in a design,” explains Leonard Christopher, product manager for NexPress, Kodak. Dimensional Clear and Light Black ink are options for all of Kodak’s presses.

Another illustration of this is the Xerox iGen 5 Press, which a features fifth station to enable orange, green, blue, or Clear Dry ink. “The gamut extending colors enable a more precise match to a wider set of Pantone colors than CMYK, while the Clear Dry ink enables a range of innovative artistic effects,” according to Bay.

Primary Applications

The number of applications possible with EP and LEP printers is unlimited. Substrate compatibility is vast, which helps the cause, as does the multiple ink options for the fifth stations found on the presses.

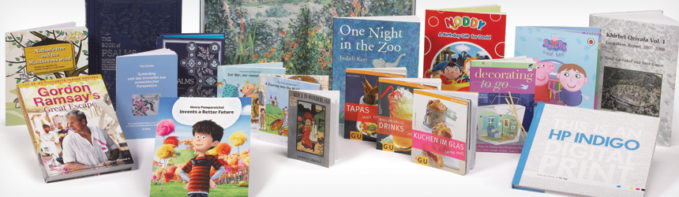

“EP supports a range of substrate weights, sizes, colors, and materials. It is generally best suited to high coverage, higher quality jobs with pictorial or photographic content,” shares Bay. Xerox customers run everything from business identification cards, billing and statements, direct mail, postcards, posters, and greeting cards to invitations and stationary, photo books, and magnets.

Mertens says that Xeikon EP devices “create a variety of high-end printed communications, crossing the spectrum of commercial print, including direct marketing and transactional print.” Specific products include point of sales and point of purchase (POP) materials and banners, coffee table books, label printing, and folding cartons.

“Common applications include marketing collateral and retail pieces that require both high quality and typical ink coverage 30 percent or more,” agrees Christopher. He also cites direct mail as a significant volume, where larger sheet sizes allow more cards to be imposed.

On the LEP end of the spectrum, HP Indigo’s proprietary LEP technology has customers producing a range of high-value applications for commercial print, direct mail, photo specialty, labels, flexible packaging, and folding cartons, according to Avi Basu, head of Americas marketing, Graphics Solutions Business, HP, Inc.

At drupa 2016, HP provided attendees with its vision for the future of LEP with the HP Indigo Digital Combination Press. The system incorporates HP Indigo print and digital embellishments in a single-pass solution. Part of the dedicated line is the HP Indigo WS6800 Digital Press, which is a narrow web printing solution utilizing HP Indigo ElectroInks. In partnership with JetFX, the HP Indigo Combination Press enables the production of digital spot and tactile varnishes, digital foils, and embellishments.

Future Applications

With its staying power, we can expect the EP and LEP segment to expand into new applications over the next few years. Vendors recognize the importance of keeping pace with popular trends and develop presses that reflect this.

New features on presses will push EP into segments like packaging and POP. Kodak introduced the ability to print on heavier weight substrates like 24 pt. paperboard and synthetics with its NexPress ZX series, which debuted at drupa 2016. It features the optional ability to print on sheets up to 48 inches in length and offers Opaque White ink in the fifth channel.

“We are already seeing an uptake in a number of specialty areas. These include wallcoverings and security printing. We expect to see these applications grow. Plus, our customers are very creative and are always pushing the envelope in terms of the applications they produce,” adds Mertens.

Basu agrees. HP expects LEP usage to grow based on broader market needs, especially because of higher value print enhancements found on the devices like specialty ink, media compatibility, and creative finishing.

Bay predicts advancement in a range of hybrid applications that leverage EP and inkjet’s individual strengths. An example would be a catalog, with the cover printed using EP—benefitting from the options of a metallic gold dry ink, and the body of the catalog printed with inkjet.

“The result is a piece with improved visual appeal, printed in a larger format size, at a lower cost—resulting in improved readership and response rate. These hybrid jobs are likely to increase as print providers take advantage of the attributes of each technology,” says Bay.

Metallic Shines

Orchard Print Services Limited, based in Daventry, UK, provides print, design, marketing services, and promotional items. Founded in 1992 by Janet Head, the company employs ten in the heart of the town, near industrial parks and villages. 75 percent of the business is split between graphic design and print for small, medium, and large businesses. The other 25 percent is from retail sales for stationary, t-shirts, and supplies.

At the end of 2016 it acquired a Xerox Color 800i Press, which complements the other Xerox presses in the shop including a Xerox Color 550 Printer and a monochrome Xerox D110 Copier/Printer.

Prior to the purchase of the Xerox Color 800i Press, the lease on a Xerox Color 1000 Press ended. Instead of renewing, Orchard Print decided to look for a printer that could better match its volume requirements. It found that and more with the Xerox Color 800i Press. The device’s capability for gold and silver metallic print in a fifth channel was an attractive feature that differentiated the company from the competition.

“The new machine allows us to be more creative and grow by offering something you can’t buy anywhere else in the area,” explains Janet Head, managing director, Orchard Print.

The new Xerox Color 800i Press was implemented in October 2016. Right away, Orchard Print set out to leverage the technology. Using the silver metallic option, it rebranded and created a new silver logo. The act refreshed the company’s image while advertising its newest capabilities.

The creative team at Orchard Print soon expanded the offering palette beyond gold and silver by mixing metallic with various colors to create shades of silver and gold, even creating a shade of bronze. It was then decided that the feature was ideal for designing wedding stationary.

Prior to the Xerox Color 800i Press, Orchard Print sourced its wedding stationary from an outside provider. However, it launched its own designs in early 2017, most featuring the metallic inks. Since the introduction, the company’s personalized wedding announcement business increased fourfold.

Besides opening up new revenue streams and rebranding its logo, Orchard Print converted a customer from analog to digital. A logistics company required personalized gold, silver, and bronze certificates for staff. Previously these were printed on lithographic presses using metallic ink and then overprinted to personalize them. With the Xerox Color 800i Press, Orchard Print produces the certificates in a single pass.

“You build a business to survive and thrive. I see the metallic inks and our business in general growing extensively in the next few years,” shares Head.

Maintaining a Presence

EP- and LEP-based presses maintain a presence despite competition from inkjet. Suited for high-quality applications with high coverage needs, the features found on both dry toner and liquid EP presses are ideal for a number of print providers. A range of applications rely on EP for its media compatibility, finishing capabilities, and fifth imaging stations. Combined, these characteristics make for a worthwhile investment, especially as new segments like packaging take advantage of the technology.

September2017, DPS Magazine