By Cassandra Balentine

One of the biggest challenges print providers face is being cutting edge without getting in too deep. Those that have successfully mastered the art of strategically investing in new technologies are at an advantage. One such company is Color Ink, a multi-faceted print business that like many of its peers, evolved to what it is today.

Color Ink is an innovative, family-owned print provider headquartered in Sussex, WI. The company started in 1984 when Jim Meissner decided to take the leap from a design studio and print broker to a print provider. Expanding rapidly, the company grew from a 10,000 square foot facility in Hartland, WI, to its current location with two buildings totaling 100,000 square feet. Todd Meissner, president, Color Ink, tells us that today the shop is still family owned, with his son joining the business as sales and sourcing manager.

The success and growth of Color Ink is partly attributed to its ability to evolve with customer needs. Todd Meissner explains that when it first opened up shop, major manufacturers were headquartered in town. But the commercial print market has changed and now its client base includes more fashion and retail customers. It does a lot of work with beverage companies, convenience stores, gas stations, and all things point of purchase (POP). But its reach doesn’t stop there. The company also reports that packaging makes up about 20 percent of its business, including both folding carton and corrugated work.

Color Ink’s capabilities are diverse, including UV printing, conventional lithographic printing, large format digital printing, small format digital printing, binding, mailing, distribution and fulfillment, and variable data. To produce this range of work, it employs an extensive equipment list, including a Komori Lithrone LS-640 and Albo Paper System PT 1800 AP DSM Pile Turner for offset printing; an Inca Spyder X, Inca Q40i Onset printer, Agfa Jeti Mira MG 2732 HS, ATC UV Roll Coater, InPro Rhino Guillotine Cutter, Zünd Digital Cutter, and Pro-Tech Orca III Laminator for wide format printing; and a Fujifilm J Press 720F, MGI JETvarnish 3DL, Komori IS29, Xerox Versant 180 Color Performance Press, and MBM Aerocut Digital Cutter/Creaser for digital printing. It also employs prepress software and equipment, full bindery, and mechanical bindery, along with mailing and fulfillment equipment.

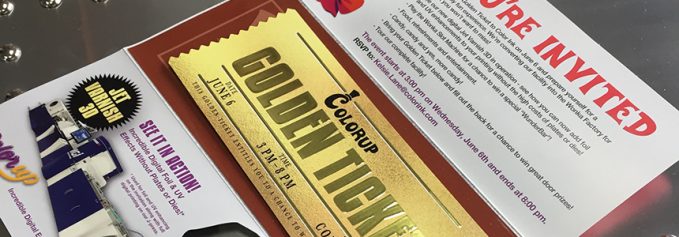

Above: Color Ink digitally printed and embellished tickets for its open house last summer using the MGI JETvarnish

Digitally Focused

Since its start, Color Ink has completely flipped its capabilities from traditional to digital print methods. Ten years ago it had four lithographic presses and very little digital, but now it’s primarily a digital shop.

One of its most recent investments is the Komori IS29, a 29-inch sheetfed inkjet digital printing system that utilizes UV inks. The print provider installed the IS29 last Summer and uses it to create folding carton packaging solutions among other applications. “We’ve been producing folding cartons for over 20 years, but fell into it by accident,” recalls Meissner. When it first added UV lithographic capabilities many years ago, peers with flexographic but not sheetfed capabilities would come to them for this type of work. It was able to produce high-end prototypes with treatments and embellishments using conventional methods. “It was costly, but there was a demand for it,” he adds.

For packaging today, Meissner believes it is at an advantage because a lot of commercial printers are hesitant to get into it. “They think, how I can compete with the big boys in the market creating 100,000s? We’ve found a couple of really good niches, including packaging prototypes and consumer products, regional brands, and businesses like craft breweries,” he shares.

Color Ink’s folding carton capabilities first expanded when it brought in the Fujifilm J Press. While it is a fully employed press, it does have limitations including its sheet size. Also, because the ink sets are water-based they are unable to print to plastics, admits Meissner.

Once the J Press was at its maximum capacity, Color Ink decided on its next machine, the Komori IS29 cutsheet UV inkjet production press. There were several reasons for this, one is its sheet size—23×39, which Meissner points out is ideal for producing stanchion signage, which are standard format graphics that its retail clients regularly request. The graphics are produced on plastic or paperboard and slide into metal frames. “Having a digital press that can produce these is phenomenal,” he shares. “When you look at store accounts, particularly fashion retail, the store counts are anywhere from 100 to a couple thousand, and they are usually requesting one or two versions of a graphic so average run lengths are 2,000 to 5,000—rarely more than 10,000 pieces. That’s why digital is a good fit.”

Innovative Capabilities

Digital print embellishment is another offering that was added to Color Ink’s portfolio last year when it purchased the MGI JETvarnish 3DL. The embellishment press features UV spot coating and foil on runs from one to thousands. The company uses the device for adding effects to output from its entire press portfolio.

The decision to invest in the MGI was driven by one particular retail customer with a contract coming up for renewal. A long-term client, they expressed the need to have a print partner that would continue to add value to its products. As retailers deal with store counts going down, the in-store experience now must be visual. “Retail budgets are shrinking but they want more value. It kept resonating with me to add more value for them. So, we told them about the textures and effects possible with the MGI JETvarnish,” says Meissner. The decision to bring in the MGI was instrumental to getting that contract renewed.

The device features a sophisticated camera system for proper registration. “Spin it, skew it, it doesn’t matter—it will register accurately. The ease of makeready and set up makes the varnish easy to run and easy to adhere across a range of substrates,” shares Meissner.

The JETvarnish offers many effects, including raised/spot UV coating and foil. Meissner says the coating effects are the easiest to market. He estimates that 75 percent of the work on the machine is from coatings. Customers can produce spot coatings over a logo or a photograph, which are simple effects to perform. “You can change the level to go really thick or thin,” he adds.

The remainder is special effect textures like patterns of coating, glitter, and sandpaper. In fact, the print provider did its own promotional piece that imitated canvas print. The machine also provides foiling capabilities, which is something Meissner says is still a work in progress, but has great potential.

In addition to serving its existing clientele, Color Ink attracted new customers—including peers—upon bringing embellishment capabilities in house.

One area Color Ink has found success is promotional packaging. Using a mix of its printing and finishing capabilities, these products are in demand from brands looking to create high-end marketing kits for sales representatives before going to market with a new product. These high-end embellished sales kits tell the story of a product. Sales representatives use them to pitch brands to retailers in order to get products on store shelves. While only a few of them are produced at a time, brands spend a lot to make them attractive and functional with dimensional elements.

On the Horizon

Color Ink is about innovation. Throughout its 35 years, the company has made strategic investments in the latest printing and finishing technologies to remain relevant for its client base. With early and frequent investments in digital printing technologies, wide format inkjet, and print embellishment capabilities, Meissner says it is now really trying to close the loop with digital die cutting. “Die cutting is a costly and laborious process, you have a die cost for each job you do,” he shares. But recent advancements in laser cutting from companies like Highcon reduce the need for steel rule dies to offer more efficient short runs.

It isn’t looking to stop there, either. The company also has its eye on three-dimensional printing, particularly watching what Massivit 3D has up its sleeve. Meissner expects to investigate this and more at the next drupa.

When it comes to investing in new technologies, “the challenge isn’t knowing that it’s coming, but finding the right time to get in,” he concludes.

May2019, DPS Magazine