DPS Magazine Staff

As businesses look to cut costs and expand into new markets, digital printing is attractive for label production. With fast turnarounds, opportunities for customization, and high-quality output, digital technologies support the latest demands for label production. It is attractive for both small businesses and start ups that don’t meet the high-volume minimum requirements of many traditional label printing methods.

Diego Rodriguez and Adriana Gutierrez recognized the need for short-run label products, and launched Labelink in 2017 as a small, 100 percent digital print provider located in Arroy Hondo, Santo Domingo, Dominican Republic.

“We identified a niche were customers demanded quality labels to represent their brands in local and export markets but were reluctant or unable to buy large stocks of labels,” shares Rodriguez.

The company has grown to a modest but expanding operation. What started as a 400 square foot shop owned and operated by Rodriguez and Gutierrez has transformed to a 1,000 square foot shop with a staff of seven.

Wide Reach

Labelink provides label output to a range of industries with solutions for food lines, cleaning products, beauty products, and box labeling. It specializes in short- to medium-sized runs of self-adhesive labels, which are produced to the specific needs of its clients.

It is focused on printing fast, high-quality, beautifully finished labels that help businesses thrive. “We believe we can grow with our clients and their demands,” says Rodriguez.

To produce its label work, it utilizes a Valloy bizpress 13R. The label press uses an advanced LED production print technology. It offers printing speeds of up to 23.8 feet per minute and 1,200×2,400 dpi. The machine also supports papers from 60 to 250 micron thick; and PET, PP, PE, and PVC films.

Rodriguez points out that as it started to expand its business, the demand and volume of its orders required a press that could support fast turnaround times and offer more flexibility in regards to the media printed.

It found the Valloy bizpress 13R, which was attractive due to its ability to use non-treated material, such as BOPP, foil, and clear BOPP. He notes that this presents a clear advantage over other digital technologies available in the market.

“The ability to process jobs quickly, on very affordable media, with great print quality is probably the biggest advantage of the bizpress 13R,” offers Rodriguez.

The print provider stocks up on a broad range of substrates and finishes to ensure a professional and premium look for any project that may come in.

Labelink continually works to educate its customers on the benefits of digital print technologies for label production. Rodriguez says one of its biggest challenges is the perception that traditional label printing is more affordable than digital printing. “Having a printer like Labelink that can produce labels in a few hours with outstanding quality and a slightly higher cost per unit, but offering shorter runs, is undoubtedly a better way to use money in developing the crucial aspects of any business,” he states.

Beer Runs

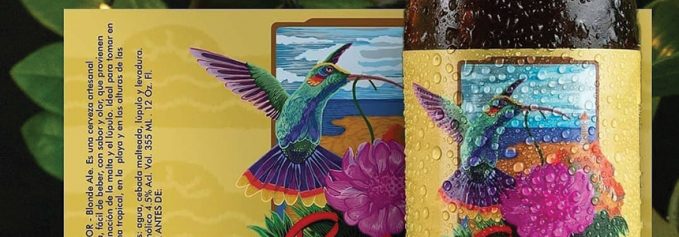

Businesses that require short runs are ideal candidates for digital printing. One industry that benefits is craft beer.

Labelink works with six local craft beer producers, many of them are fulfilling customers’ orders of as little of 500 bottles for special events, which can be personalized for any occasion.

In addition, the print provider handles the breweries’ monthly label demand based on what their sales teams require. “This flexibility allows them to place orders of 2,500 labels on ‘slow’ selling months and to up to 25,000 labels when demand is higher,” explains Rodriguez. Through Labelink the breweries are able to get necessary labels in just a few days.

Focused on Quality

Labelink is committed to its customers and offering high-quality output for a range of label products. It plans to keep adding value to its product offering. In the near future it has its sights set on investing in embellishing and finishing options to provide a wider range of possibilities in the self-adhesive labels market. dps

Jul2021, DPS Magazine