By Olivia Cahoon

Print service providers (PSPs) use print management information systems (MIS) to automate daily tasks and manage inventory, consumables, prepress, post press, graphics, and pricing from digital to large format and often include integration with CRM and scheduling, reporting, and payment functions.

Print MIS is an investment that requires time, effort, and startup costs that may deter PSPs from implementation. We spoke with print MIS vendors to determine indicators for investment and how the technology benefits digital printing environments.

From Stressful to Simple

Print MIS software works with a PSP’s existing digital or hybrid print workflows. In the commercial print space, this includes integration with leading prepress workflows. Packaging providers also achieve end-to-end integrations for analog, digital, and hybrid production environments.

“End-to-end workflow is about achieving an overall business objective of growth, diversification, and improved profitability, and while single or point solutions can help with these, they often only move the core issue further downstream,” according to Nick Benkovich, senior director, portfolio management, EFI Productivity Software.

MIS offers visibility, control, and efficiency. Stephen McWilliam, EVP, Avanti, explains that accessible information maintained by MIS creates better decisions. The software manages and tracks the cost of hundreds of jobs per day and eliminates required touchpoints to finish jobs.

MIS solutions reduce the time and effort needed to complete web to print (W2P) storefront orders through production—orders are shipped with minimal input. Joseph Lehn, product management director, PressWise by SmartSoft, says fully integrated systems are designed with the basic premise to keep touch points to a minimum.

Dorothy Asboth, North American sales manager, Label Traxx, says studies show the number of orders in a print environment can double with digital. “We see the biggest payback for those shops that see a large amount of reorders, like label converters.” Print MIS encourages job data to be consistent so job specifications are easily repeated on press for each product run.

Tulin Edev, VP, Printer’s Plan, says MIS software often includes features like print estimating, order management, inventory management, in-depth reporting, data exporting, and web solutions. Its features have the required tools to manage a digital hybrid printing business.

MIS Cautions

While MIS software offers control, some companies haven’t yet invested in MIS. The most apparent inhibitor for these companies is resistant to change. Organizations must be willing to move through change management and invest in an end-to-end workflow.

In addition to change, PSPs must also be willing to invest time. “With company margins as limited as they are, printers run with a minimal amount of staff, which makes the thought of taking the time to implement a new system difficult to contemplate,” says Lehn.

Lee Ward, global sales director, Tharstern, agrees and says small companies consider the implementation process as neither quick nor easy. “It isn’t a plug-and-play solution and companies have to invest time, effort, and capital to get it working,” he states.

Benkovich says many of these companies are smaller businesses that consider MIS to require too many resources in terms of IT infrastructure.

Startup costs also inhibit PSPs. Unsuccessful prior attempts to implement a system concern potential prospects. Morrie Brown, president, Printpoint, explains that lack of effort either within the PSP’s shop or poor support from the MIS vendor leads to frustration. A desire to match prior pricing may lead to irritation when the shop doesn’t understand the pricing system it was dependent on—resulting in an inability to articulate pricing and bring them to an automated computer system.

Besides the actual cost of software, PSPs must also consider operating costs. Peter Dhondt, business development manager, CERM, explains that PSPs need to invest in server hardware, software modules, software maintenance, and web hosting.

Jordan Melick, business development manager, Accura MIS, says MIS provides the ability to perform many functions from a single entry point, allowing users to be more efficient.

Observing Workflow

Certain indicators help PSPs determine if implementing a print MIS solution is viable. For PSPs handling large volumes of digital print jobs, print MIS helps optimize job distribution, throughput, scheduling, and asset utilization.

“Those types of extremely automated, streamlined workflows work with very few touch points but are also scalable to different print production needs,” explains Benkovich. Single-location offset and digital print shops experience similar efficiency and growth in the technology implementation of wide format inkjet signage and graphics businesses. Short-run printing indicates higher order volume that leads to more invoices, estimates, and job tickets. Benkovich adds that the increased need for these tasks on a higher frequency of short-run orders creates increased automation in digital print production and business management workflows.

McWilliam states that PSPs who have growing and difficult to manage shops, are moving into different segments, or have unfulfilled customer requests due to lack of processes, consider MIS solutions. “As more businesses add new lines of business, whether it be digital equipment or marketing services, a print MIS streamlines workflow, eliminates islands of automation, and ensures the tools to stay on top of the operation.”

Other indicators that suggest it’s time to implement a print MIS include lost orders, customers questioning inconsistent pricing, an irregular path of orders, and a lack of integration from the W2P storefront to job ticketing, production, shipping, and invoicing. “Re-keying of information from one system into another is a clear indication of time that could be better spent producing new work,” says Lehn.

Digital printing requires the organization and management of many digital assets and files. Lehn explains that MIS software provides an organizational system that allows more time—especially for short print runs that create less margin with less working time.

Nate Burns, sales manager, Virtual Systems, says PSPs considering an MIS solution should move if they have experienced redundant data entry, customer service issues, or mistakes regarding incorrect estimates, issues in production, or missed billing items.

“Everyone can benefit from a print MIS solution. Chances are most of your competitors already have it and as a result, their overall costs are lower as they are able to operate more efficiently,” states Usman Ali, principal, Ordant.

Justifying Costs

Investment in print MIS is justified by ROI. Some enterprise resource planning or MIS solutions calculate the advantages of improved profit per order and faster turnaround times.

Benkovich shares that additional benefits include increased customer satisfaction measured by improved, real-time feedback, and improved employee morale as a result of faster, simpler, and more fulfilling work.

McWilliam estimates a ROI of ten to 14 months, partly due to time saving features and software that handles multiple lines of business. “In shops without a system, we have found customer service representatives spend 20 to 25 percent of their time chasing information for their clients and sales teams.”

To establish ROI, Lehn says it is effective to evaluate the current workflow costs by identifying the steps needed to push a typical job through the shop. These include manually generating quotes, keying in orders, delivering proofs, making changes, scheduling jobs, creating shipping labels, entering job data into an accounting system, and prepress tasks like downloading files, preflighting, and impositioning. The information is used to determine and analyze the typical number of jobs run per day and the average time spent performing each step. The total average hourly cost for employees that perform these tasks is then calculated.

“Armed with this data, it is possible to streamline the workflow with an automated print management solution that identifies where the savings can be made,” says Lehn. The process determines projected ROI before purchasing and implementing an MIS system and determines ROI after implementation.

Print MIS systems have monthly service maintenance fees and startup costs. ROI justifies how savings will outpace costs. “There is investment in the software and in the training, but the time savings more than makes up for that,” adds Lehn.

High- and low-volume shops benefit from different print MIS features. A high-volume shop benefits from features like data collection, inventory tracking, W2P, and scheduling. “Typically, a low-volume shop benefits from estimating, basic job tracking, and invoicing,” says Brown.

According to Rich Giles, president, AACRO Computer System, the greatest benefit to a small printer is the ability to quickly produce and transmit quotes. “This means that multiple quantity quotes take the same amount of time to generate as a single quantity quote,” he adds.

High-volume shops profit from the ability to run a job through all of its processes without constantly pulling it out to accommodate changes, says Carol Andersen, chairman, EPMS. Electronic job monitoring and data collection alerts the shop of the job’s status at any given time. Change order functionalities allow instant changes on electronic job tickets.

Optimized Print

The size and scope of a print provider, as well as customer demands, dictate the level and importance of print MIS within a digital print environment.

Founded in 1981, Quality Press is a print shop in Seattle, WA, that offers 24/7 cloud-based online ordering, proofing, and order history access as well as prepress services, one- to five-color offset, digital, and letterpress printing; four-color and white printing on glass, ceramics, and metals; and finishing, mailing, kitting, fulfillment, and distribution.

John DePasquale, owner, Quality Press, purchased the shop in 2008 with 12 employees. Quality Press now has 25 employees in a work area of 11,777 square feet—providing services internationally. The company’s mission is to work with clients for the best results with a mutual understanding and a shared purpose. If it is unable to create a solution in house, the shop will find a way to get the job done.

Quality Press produces general commercial printing, corporate identity, folding carton, variable data, and assembly. The shop uses the HP Indigo 5600, which prints at 90 pages per minute for more than two million color pages per month.

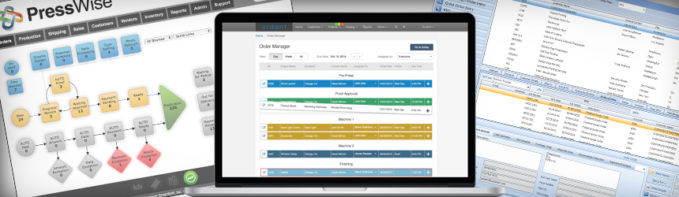

For two and a half years, Quality Press has used PressWise workflow software. PressWise is an end-to-end Software as a Service-based MIS and print workflow automation solution complete with unlimited web storefronts, estimating, quoting, order processing, workflow management, complete shipping integration, fulfillment, and an ability to integrate with most third-party storefronts and existing backend accounting systems.

PressWise dedicates its MIS solution to helping customers decide the most appropriate solution for business—whether creating a single unified workflow or keeping digital and offset workflows separate.

“It’s fast, seamless, lean, and available to all employees wherever they are as long as they have an internet connection,” says DePasquale. PressWise’s MIS solution is intended for an target audience of commercial printers with a reported revenue between $1 to $10 million annually.

The PressWise workflow solution offers a variety of core functions, including print estimating tools to help users save both time and money, order management to control business flow, production management for a top-down view of orders by job status, inventory management to automate materials and finished goods and stock, and mail processing to capture incremental revenue. These capabilities help users become one-stop shops.

“It’s faster to estimate, enter orders, and communicate with customers than ever before,” says DePasquale. He adds that his customers love the automatic proof, invoice, delivery, and shipping notifications that the solution provides. Additionally, estimating, access to customer data, and storefront capabilities are faster than ever before.

Print MIS

Low- and high-volume print companies are both candidates for MIS. Today’s solutions are targeted to save time and produce high ROI for PSPs. However, print providers who have not yet integrated MIS are wary of the effort and costs needed to implement these solutions. Despite this, PSPs may determine if a MIS solution is a fit by comparing the options. From modular to complete end-to-end solutions, print MIS software is on the market to serve every print environment.

Mar2017, DPS Magazine