by Melissa Donovan

With growing interest in short-run packaging and prototyping, digital print providers require finishing components that keep pace with the prints being output. Commercial printers look for alternatives to traditional die cutters and turn to smaller digital flatbed cutting systems, which offer versatility to finish a range of solutions from adhesive sheets, business cards, specialty shaped cards to invitations, small packaging, and tags.

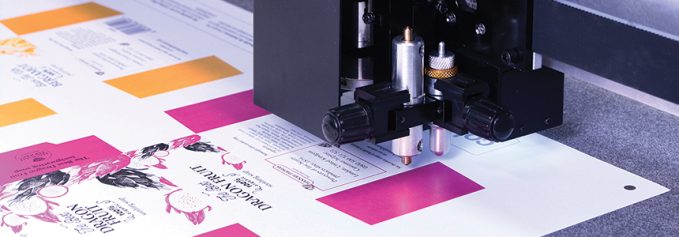

Shown: Intec’s automated flateds are focused on offering unattended capability for a tabloid/SRA3 workflow.

Demand Drivers

The adoption of digital flatbed cutting systems in the commercial space continues to grow primarily because of the many advantages that these solutions—specifically ones under 32 inches—bring to the table. For the purposes of this article, we’re looking at B2 format—19.7×27.8 inches and B3 format—20.24 inches, at a maximum width of 32 inches. Limitations are few and far between.

“The adoption of digital die cutters is a result of the varying run lengths commercial printers are faced with primarily in digital print shops versus offset,” attests Max Allen, director of wide format, labels, and packaging, Graphic Whizard.

According to Quentin Edwards, digital series product specialist, Cutworx USA, demand for die cutting in the commercial space is rising. “Traditionally, a die would be made for rotary die cutters in order to process jobs. With sheetfed digital die cutters, the need for the die is eliminated. Short-run production can now be brought in house. Companies can bring in the small quantity jobs and produce quick turnaround times instead of outsourcing. Blade-driven cutters also allow for variable die lines on single sheets. For example, you could produce tags and unique cards on one sheet and pocket folders on the next sheet.”

Terri Winstanley, product and marketing manager, Intec, sees growing demand for unique and specialist applications as well as general commercial work. This is driven by clients that require shorter run lengths and shorter lead times.

In reference to the small size of the devices, Matteo Muto, sales and marketing manager, Valiani srl, sees it as a benefit instead of hinderance. “The main benefit they offer is of course the compact size, their reduced footprint in a working space so as to facilitate moving. Another important aspect has to do with shipments. Shipping a small device is much lighter and cheaper than very long tables. Also, if you start entering a new business but you don’t want to invest too much money on a large table, small-sized cutting plotters are the ideal solution to start from scratch a new activity.”

“Demand for these cutters for commercial spaces is to offset the short-run jobs and one-offs from larger cutters and provide customers with quicker turnaround times,” explains Anthony Blanco, print embellishment, technical support supervisor, Duplo USA.

Limitations, according to Allen, involve thickness and density of substrates. “Our die cutting systems can cut up to ten millimeters thick with an electronic oscillating tool (EOT), but wide format cutting tables can cut much thicker and harder materials with a router.”

Tooling Options

Finishing commercial items like packaging, unique cards, stickers, and labels requires specific tooling and features like a digital registration system.

Oscillating and tangential/dragging knives are popular tooling options. “Regarding packaging applications such as business cards, small boxes and displays, racks, and also packaging-related ones such as stickers, labels, and decals, you always have to bear in mind the fact that some media needs to be cut by an oscillating knife, while some others prefer a tangential/dragging knife,” explains Muto.

“A variety of tooling options are available for small format digital cutters to achieve specific applications. Use regular drag knives to process cardstock materials such as tags, cards, envelopes, pocket folders, and invitations and kiss cut tooling to produce labels and stickers on adhesive sheets,” agrees Edwards.

Perforation and V-cut tools are common for packaging. “Creasing options are available with perforation wheels and even V-cut tools to cut 90 degree angles for folding. Use these creasing options along with an EOT to cut materials up to six millimeters in thickness. Create corrugated packaging, point of purchase displays, and signage with these tools,” shares Edwards.

“Major companies also have other devices, such as V-cut tools to perform very peculiar angles, particularly appreciated in the luxury packaging field; and rotary knives and routers to cut harder and more consistent materials,” notes Muto.

In addition to standard tools for cut and crease, machines are expanding into features like gluing inline.

“All tools are specific to the materials being converted and also if the machine can offer it. Cut to print accuracy is one of the most important requirements, so the registration system and its flexibility for finishing is crucial to the process,” says Winstanley.

Digital registration systems “play a role in allowing CCD cameras to register crop marks in order to process materials. Otherwise, we could not calibrate offsets for cutting,” says Edwards

For example, the DPC-600 Digital Die Cutter features DPC Connect software, which connects with a camera registration system to read generation marks to compensate for image shifting and allow for quick changeovers using quick response (QR) codes printed on the sheet.

Graphic Whizard includes control center software on all of its systems. It allows users to easily select tools, control depth, load jobs, read barcodes, and automatically scan registration marks to align perfectly to each sheet, regardless of image shift.

Into the Flow

Digital flatbed cutting systems must be able to automate and integrate into existing commercial workflows. Thanks to partnerships with many third-party software vendors this is fairly easy to accomplish.

Duplo partners with EFI, which enables an automated workflow through software like Jobflow and Prep-it. “When utilizing this software, the user can quickly drop a one-up PDF from their desk. The workflow will nest/impose then add the necessary registration marks with a barcode, leaving the user to print then drop sheets into the feeder and press the run button,” explains Blanco.

Small flatbed cutter manufacturers may equip their cutting plotters with certain software so they work well with printers—digital or offset—that include optical systems. “These are high-resolution cameras, which allow to detect printing crop marks and make precise contour cuts on pre-printed images. Once the camera is positioned on the first registration marks, this optical system automatically detects the subsequent marks,” shares Muto.

Digital cutters are able automatically register sheets with registration marks, creating an opening for operators to work on other projects. “A designer can create files for print and cut. Send one file for printing and then place the printed materials onto the feeder. The operator will then import and set up the cut file for processing. Variable data printing and prepress options from RIPs to preflight files. Programs allow for use of QR codes to further add automation when streamlining file preparation and cutting,” notes Edwards.

Investing Forward

It is important to examine all of the options when looking for a new cutter.

Blanco says that the investment in digital can be up to 50 to 80 percent less expensive than traditional die cutters. “With a digital die cutter, there’s no need to purchase a die plate, and it only requires a cut file in PDF format. This will save the user downtime and money and allows them to manipulate the cut files on the fly when needed.”

Muto agrees, noting that with these devices there is no need to pay for a custom die; plus, you can create more intricate shapes via digital cutting. “Based on market research and sector journals, the printing market is experiencing a period of great growth in the digital sector. This is mainly due to a sharp reduction in the quantity of orders but with a substantial increase in the variety of demand.”

When looking at the numbers, Graphic Whizard digital die cutters are a quarter to half the price of a wide format cutting table depending on the size of the machine, according to Allen. “The largest savings aren’t the machines themselves, but other the zero cost setup and labor free operation. Many of our customers currently have wide format cutting tables, but manually loading and unloading those machines is too cost or time prohibitive for short-run digital jobs.”

Small Flatbeds

Small flatbed cutting tables are designed for the production of commercial items like packaging, unique cards, stickers, and labels. These devices offer the same features of traditional rotary die cutters but are ideal for short-run jobs and quick turnaround demands that so many commercial printers are experiencing today. dps

Jul2022, DPS Magazine