By Cassandra Balentine

Transactional service providers understand the importance of quick turn times and continue to evaluate processes to eliminate redundancies and improve efficiency. A White Paper Factory is one way this is achieved.

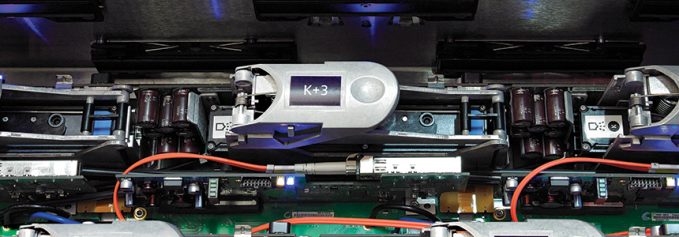

Above: Barton & Cooney operates BlueCrest IntelliJet 20 machines, which are designed to produce transactional mailings at up to 500 feet per minute with up to 2,400 nozzles per inch native resolution.

With the latest in advanced workflows and inkjet printing, data service providers can process data on the front end and come out with accurate output on the back end. This process reduces the need for stocked shells and facilitates a flexible, on demand print environment.

Barton & Cooney is a data service and communications provider based in Burlington, NJ. Founded in 1969, the company operates one, 85,000 square foot location. The company employs 100 staff members and serves clients across the U.S.

Combining best-in-class hardware and software with knowledgeable, attentive, and personalized service, Barton & Cooney creates Central and Southern NJ’s largest and most experienced printing and mailing operation.

A second-generation family-owned business, it initially focused on lettershop and fulfillment services, later expanding with digital printing capabilities.

These services, along with a talented staff, make the company one of the industry’s finest printing and mailing providers.

Printing and IT

Barton & Cooney operates with four core categories—digital print, offset printing, letter shop, and information technology. On the digital print side, broadly speaking, it handles specialty printing, direct mail, inserts, financial printing, and forms.

“There are not too many companies that can offer our breadth, experience, and quality,” shares Pat Doyle, owner/president, Barton & Cooney.

The company’s transactional businesses utilize a white paper factory approach. In 2014, the company invested in BlueCrest technology. This decision was based on a variety of reasons. “Turnaround times were and are getting ever more challenging and it was increasingly tough to meet these tight time frames with our existing technology,” explains Doyle. Additionally, it sought the capability and flexibility to respond confidently to new business opportunities. “Increasing competition and commoditized pricing meant that we also wanted to drive down operational costs in order to provide clients with a lower cost per piece for printing.”

The company already had a strong relationship with BlueCrest, as it has used iterations of BlueCrest’s Flowmaster and FPS inserting systems for several years.

BlueCrest’s White Paper Factory solution includes two IntelliJet 20 Printing Systems. The presses consolidate workflow by using rolls of plain white paper rather than pre-printed forms, improving speed, accuracy, and precision.

In the past Barton & Cooney was processing all work on a combination of Xerox continuous form printers and six or seven cutsheet printers. On the continuous form systems, it imaged black only on pre-printed shells. The cutsheets were a mix of B&W and highlight color.

It can process more types of applications on two BlueCrest IntelliJet 20 printing systems, which provides high-quality, digital color print and can process a range of applications. “It moves monochrome work from toner to inkjet, lowering running costs and greatly improving our turnaround. Through versioning on the fly, we substantially reduce our clients’ postage costs and handling fees,” comments Doyle.

The transactional printer was able to reduce operating costs and increase throughput by 50 percent, as well as lower employee full-time equivalents by two. “We’ve gained new functionality and capability, including more types of jobs on a range of substrates as well as the ability to print hundreds of variable jobs,” says Doyle.

“With the IntelliJet 20 Printing Systems we can meet the demands of our clients for quicker turnaround from receipt, print, to post. Previously, we were able to produce 300,000 images daily on two toner printers whereas now we can produce 1,000,000 images daily on our two IntelliJet 20s” says Doyle.

The company is now able to respond quickly and confidently to new RFPs and has won new work on the back of this investment. “Our White Paper Factory capability reaffirms Barton & Cooney’s position as a major player in the marketplace,” he adds.

In addition to the IntelliJet machines, Barton & Cooney strives to be a one-stop operation for all client requirements for any direct mail campaigns or transactional work. It operates BlueCrest intelligent inserters can process all letter types of envelopes from monarch up to 10×13-inch envelopes. It creates Mail Run Data Files for any job requiring 100 percent integrity or 100 percent completion.

Inserters have inkjet printing inline for match mailings. The shop floor also features MCS high-speed Eagle printers, tabbers, card affixers, meters, and stampers.

Added Channels

The company also supports email statement delivery and notification. It leverages Amazon Web Services, Sendgrid, and .NET to develop these applications.

“We have several applications that use a print/email hybrid. In some cases, we segment our statement processing delivery between print and email customers. Also, for direct mail campaigns we send a print document as a follow up after an email has been read or if an email was not read in a specific period,” says Doyle.

While it supports electronic delivery channels, currently 100 percent of its multi-channel campaigns include a print element. “That has stayed consistent over the past few years, but we expect non-print campaigns to become more common in the future,” explains Doyle.

He says that although it has seen email statement delivery making gains within the business-to-business space, print remains the most successful and the one its clients—for now—continue to prefer.

Transactional Trends

Barton & Cooney understands the importance of efficiency and flexibility. With a White Paper Factory approach, the company eliminates the need for pre-printed stocks in favor of a leaner operation. dps

Mar2021, DPS Magazine