by Cassandra Balentine

Environmental, generational, and cultural circumstances push the print industry towards shorter, more personal, and targeted print. With the help of automated and integrated workflows, print providers embracing digital technologies are well positioned for success in a shifting market.

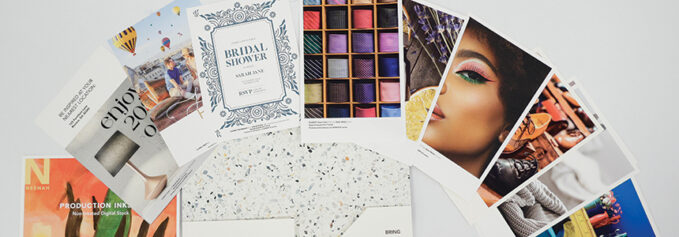

The technology advancements fueling growth and adoption of digital print include the advancement of production inkjet, artificial intelligence (AI), automated workflows, and growing sustainability practices, according to Tonya Powers, senior director of marketing, Canon Solutions America, Production Print Solutions.

Craig Powell, GM, North America, printIQ, agrees, adding that the future of the print industry is shaped by advancements in automation, personalization, and sustainability. “Automation technologies like AI, machine learning, and smart workflows are optimizing print operations, reducing errors, and increasing efficiency. The growth of digital printing, including inkjet and on demand printing, is allowing for more customized and personalized print solutions while eco-friendly materials and sustainable practices are becoming priorities. Additionally, cloud-based print management systems enable remote access, streamline operations, and enhance collaboration.”

As we close out 2024 and move into 2025, Marc Raad, president, Significans Automation, predicts an increased focus on sustainability, a continuous shift toward personalization and customized printing solutions, along with increased growth in textile and wide format print. Data protection from cyber threats and the rise of smart interactive packaging are also noteworthy trends.

Aron Allenson, product manager, high-speed continuous-feed inkjet, Screen Americas, says the industry continues to move towards automation, running cost reduction, efficiency, and higher quality.

Digital Transition

Advanced workflows and digital print and post press equipment are essential to a modern print environment.

The transition to digital print allows for greater flexibility, efficiency, and the ability to handle short-run orders with quick turnaround times, meeting the growing demand for personalized and on demand printing services, shares Dmitry Sevostyanov, CEO, Customer’s Canvas.

Simon Lewis, SVP marketing, strategy and business development, Highcon, adds that this transition also includes full integration of printed products, whether packaging or commercial print into the online digital ecosystem. “It’s much more difficult than it was 20 years ago. But it can be very rewarding.”

Rolando Martinez, head of Pagewide commercial products and solutions, HP, points out that while other industries struggled during the pandemic, ecommerce sales topped $1.1 trillion in 2023 in the U.S. and are expected to reach $1.7 billion by 2027. “This continued boom is driving major print on demand opportunities as digital buying behaviors revolutionize demand. As commerce shifts online businesses require smaller, customized print runs that can match rapid ecommerce delivery speeds and expectations.”

Lower inventories and smaller batch sizes may also lead to enhanced client relations. “Partnership and communication will strengthen companies rather than maintain classic transactional buyer-seller kinds of relationships,” explains Lewis.

Short-run digital printing enables the on demand production of books, collateral, magazines, printed materials, packaging, invoices, direct and transactional mail, branded unboxing materials, return labels, and more. “The agile approach allows variation in colors, finishes, and designs too, unlocking unique branding and marketing opportunities,” offers Martinez.

Of course, offset technologies are still standard for many print providers.

Andrea Connor, worldwide solutions marketing manager, Kodak, points out that while this year provided clear evidence that we are living in the “and” era of print, “digital has arrived but offset still dominates.”

Going forward, Connor says the printing industry can expect a more fluid combination of technologies, enabling printers to maintain efficiency and profitability. “The flexibility to select the most appropriate solution for any given situation—be it analog or digital printing—will be key to navigating shifts in market conditions and consumer expectations. This strategy ensures that print service providers can utilize the advantages of both technologies to enhance their operations and outputs, paving the way for a more adaptable, proactive, and sustainable industry,” adds Connor.

Lance Martin, VP product marketing, Komori America, believes that inkjet technology—along with the proliferation of the B2-plus sheet size—will continue to develop, complementing traditional methods. “Furthermore, connected automation will develop to the point that companies will realize the concept of the smart factory.”

Dustin Graupman, senior director, inkjet division, Kyocera Document Solutions America, Inc., feels that the print industry is at a crossroads. “While legacy companies made difficult decisions regarding manufacturing and staffing, other production toner companies took significant cost-cutting measures to restore financial stability. This has led to one of the major trends we’ve seen—the growing adaption of inkjet technology as a primary printing method. The advancements in inkjet technology have resulted in greater adoption and companies beginning to purchase multiple devices. This leaves those who have been hesitant to adopt inkjet in a make-or-break situation.”

While Jesse Heindl, marketing manager, RISO, believes there will always be a need for more sophisticated, seven-figure cut-sheet or roll-fed production units, he expects it is light production toner as well as inkjet devices that drive the industry for the near future. “Higher costs have led to less printing and those that are printing are doing so in smaller batches. It’s all about spending money tentatively and carefully. Smaller and more affordable units will drive the industry. The benefit of inkjet lies in the fact that it uses no heat, which means parts have a much longer life span. All lowering the overall print cost.”

Sevostyanov also sees a trend towards convergence, where printers become more universal by expanding their offerings to include business printing and packaging solutions. “This shift enables companies to tap into new markets and provide a broader range of services to their clients, helping them stay competitive in an evolving industry. They’re also exploring new, more profitable niches to diversify revenue streams and adapt to changing market demands.”

This has commercial print providers expanding into labels and packaging.

In the label space, Steve Lynn, director of labels and packaging, Durst North America, sees 1,200 dpi high-speed inkjet as a technology changing the market. “Digital was historically perceived as only for short-run and variable jobs. Inkjet was historically perceived as not good enough to replace flexographic and toner in the prime label market. Those days are gone, 1,200 dpi inkjet delivers the quality, speed, cost of consumable, and efficiency that can allow a converter to run short-run and multi SKU jobs efficiently with low waste at high speed, and also run medium/long-run jobs with minimal waste at high speeds, very cost efficiently.”

Rodney Pennings, sales director, print and packaging, BW Converting, foresees continued, digital advancements fitting a broader section of the flexible packaging market, both in widths, speeds, and application fit for use.

Beyond CMYK

Digital print embellishments that offer effects like foil and embossing as well as specialty colors and gamut extensions are popular.

“Shelf space is at an all-time premium at retail stores so anything to make a product stand out will captivate the shopper and influence the buying decision,” comments Jeff Leto, VP, NBi FlexPack. For example, NBi recently installed a Cast & Cure system on its eBeam. “Cast & Cure creates holographic effects on the packages that really make them pop. It also adds an additional layer of brand protection since it is more difficult to reproduce, especially when imaged with custom holographic logos and not just effects. This technology is impactful in giving customers’ brands star power to beat the competition and protects their products from counterfeiters making knock-off brands.”

Mark Geeves, director of sales and marketing, Color-Logic Inc., agrees, adding that personalization and print embellishment will continue to grow because brands need to stand out from their competition. “This has been shown in the world of labels and packaging for years, but is now also becoming a requirement for other print media like direct mail, signage, point of purchase, and the emerging market of name, image, likeness in sports.”

AI

The hottest technology trend is without a doubt AI. Its evolution brings both opportunities and challenges.

Nir Zarmi, SVP, Landa, believes that the rise of generative AI opens up exciting possibilities for dynamic graphic design and communication. “This technology enables brands to produce a broader variety of visuals and adapt messaging quickly to different audiences or regions, fueling the trend toward shorter print runs. The ability to create unique, AI-driven artwork on demand means brands can tailor campaigns more precisely, making digital presses with high-speed and high-resolution capabilities ideal for these agile, creative applications.”

Terry Antinora, SVP, head of product and engineering, Xerox Corporation, sees the industry continuing to shift from traditional offset printing to digital printing, with AI and generative AI integrated more to improve efficiency, simplify design, and enhance specialty printing.

“AI is rapidly making inroads in many industries, and print is no different,” agrees Don Dubuque, director of marketing, Standard Finishing Systems. “While still in the early stages, we see many areas in which AI-powered systems could dramatically transform print including improved quality and efficiency, production scheduling, preventative maintenance, personalization, sustainability, and advancing automation even further. Just as when automation was introduced to the industry many years ago, I believe the companies that successfully incorporate AI early on will have a distinct advantage over those that don’t.”

While many companies are adopting AI for various applications, Raad points to studies revealing that a significant percentage of printers still have not integrated AI into their workflows. “According to an August 2024 report by Keypoint Intelligence, a huge 94 percent of 450 U.S. business leaders surveyed across various industries were already using AI in some way. Despite this, about 90 percent of U.S. printers have not even begun to use the technology. AI may still be in its infancy, but it’s destined to grow by leaps and bounds and is arguably one of the most important technologies created to date. Embracing these technologies is essential for ongoing growth and relevance in an evolving marketplace,” continues Raad.

While AI brings new possibilities, it can be challenging to figure out how to use it to one’s advantage and how it will affect the industry in the long term. “Digitalization, cross-media, and highly personalized content will continue to grow and become standard instead of an option,” says Randy Hardy, representative, North America, locr GEOservices and MAPS.

Pat Harnett, director of portfolio and development, HP Specialty Printing and Technology Solutions, says AI is bound to play a more prominent role in coding and marking systems. “The integration of AI will enable real-time adjustments, error detection, and predictive analytics that will optimize print quality automatically based on product type, environmental conditions, and production line speed.”

When it comes to efficiency and effectiveness, AI is a critical piece of the puzzle. “It is important to do things correctly the first time versus trial and error, or being able to be more efficient in your operation when it comes to workflow. AI can make you more efficient and make operations more streamlined,” offers Dino Pagliarello, VP, product management and Production Print, Sharp.

John Henze, VP, marketing and sales, Fiery, adds that AI has the potential to solve some of the most challenging problems in printing by automating routine tasks and making everything run more smoothly, from scheduling to resource management. As more AI features are introduced into the market, printers can drive additional efficiencies, reduce waste, and improve sustainability and profits.

AI also enables print providers to price out jobs more effectively and better understand what the consumer is willing to pay for certain output. “For example, it can be difficult to understand what your uplift could be on a particular sample that has metallics, varnish, or another type of special effect. There are software programs that now leverage AI and allow the commercial printer to charge the appropriate amount of money for that type of output. AI is going to be a big part of the technology that helps drive the growth of production print in terms of both profitability and efficiency,” adds Pagliarello.

Automation

Automation is expected to play a critical role in gaining efficiencies, improving flexibility, and turnaround time, all while driving down costs, shares Antinora.

Michael Matthews, product manager, DP Color, Domino Printing Sciences, points out that companies turn to technology that will help them be more efficient to stay profitable, with automation of both software and hardware emerging as popular options to help converters streamline production processes.

AI will have an impact on certain sectors, but the bigger focus will be on automation and combining tasks to drive efficiency. “Where AI can improve that, it will help and gain acceptance, even developing creative and iterations for marketing purposes. I also believe that the future of robotics is starting to filter out into more and more industries, and over the coming years, we will see more of that in place where it makes sense. Some companies offer that in the mailing and printing space today and I think it will only grow from here,” says William Longua, senior director, Digital Print Group, Quadient.

Print inspection is an area where automation is increasingly important. “Conventional print inspection uses an array of cameras, optics, and lighting to provide inspection coverage across a defined field of view,” explains John Butler, senior director, North America Sales, Teledyne DALSA.

Advancements in imaging technology provide manufacturers with the ability to utilize a single imaging module with integrated optics and lighting in place of multi-camera configurations. “These systems can be easily scaled in 100 millimeter increments with minimal engineering investment and offer high resolution and high-speed imaging capability along with the potential to cover wide conveyors or printing webs. The net result is a more cost-effective solution than many conventional systems without compromising image quality or inspection accuracy,” notes Butler.

Andy Fetherman, president/CEO, Muller Martini Corp., points to fully integrated smart factory solutions that reduce labor, minimize waste, and allow for the production of more products per square foot and labor hour as the technologies that will drive the printing industry going forward.

Automation also offers a solution to one of the biggest challenges currently facing the future of the industry, access to skilled labor.

Automation directs hardware to do things in line so labor is required to finish an output, comments Pagliarello.

Dubuque points out that while some of the challenges facing the industry may be temporary, like high interest rates, the skilled labor shortage has persisted. “While equipment providers have highlighted automation for a decade now, drupa and Printing United showed that manufacturers are going all-in on end-to-end automation coupled with user-friendly interfaces to help alleviate the challenges that their customers—both large and small—are facing.”

Sevostyanov agrees, noting that companies are focused on improving automation to enhance efficiency and reduce reliance on manual labor.

The ability to conduct preflight checks on a customer’s desktop before file submission is increasingly important in the print industry, aligning with several key trends and technologies. “Digital printing is growing due to its speed and quality, emphasizing the need for ready-to-print files. Automation and AI enhance operational efficiency, allowing integrated preflight checks that catch issues early. Sustainable practices emphasize efficient file preparation to reduce waste, while web to print solutions streamline online submissions with automated quality checks. Additionally, verifying personalized designs before printing becomes crucial as demand for customization rises. By leveraging these trends, printers can improve service offerings and efficiency while meeting evolving customer needs,” shares Mary Gay Pettit, public relations, Markzware, Inc.

“I expect automation to continue to improve in all phases of production and spread across every corner of the industry,” offers Dubuque.

Martinez points out that with increased automation and digital production there will be elevated concerns over cybersecurity. “Companies need to ensure they have strong technology partners that provide secure and proven solutions.”

Integrated Workflows

Integration is another buzzword arming print providers for success.

“We’ve mentioned automation as a key technology that will eventually become the standard for all print businesses. But automation is just one part of a broader digitalization of the industry. What will really separate businesses in the future is how efficiently their digital workflows are integrated into the rest of their processes, from their online portals, distribution channels, and sophisticated design tools,” says Piet De Pauw, head of marketing, Enfocus. “The line between the physical print product and the digital world will continue to blur with the use of augmented reality, smart packaging, and digital distribution that relies on the internet of things to provide greater transparency throughout the supply chain.”

Workflows optimizing different segments—packaging, labels, commercial, promotional, and book printing—under one roof is a trend, notices Santosh Mulay, VP, business development, InSoft Automation Pvt. Ltd.

Further, Powell indicates that data-driven decision making helps companies optimize production and better anticipate customer needs.

Manufacturers are starting to leverage data analytics and data-driven decision making. “The connected factory provides a means to collect data on manufacturing systems and provides powerful insights that can be used to better optimize print jobs, enhance the quality of finished products, reduce waste, and minimize costs. These advancements will help to ensure that the industry remains competitive and healthy in the years ahead,” notes Butler.

Raad says his team has utilized AI for the automation of prepress checks, layout optimization, faster processing of large volumes of data, and much more. “We’ve been deploying specific AI technologies into our workflows for some time now. This allows us to analyze large datasets, convert legacy data, and identify meaningful patterns for print shop owners to make better-informed decisions based on accurate data insights. AI reduces errors, enhances production efficiency, helps manage inventory, estimation, and much more.”

Aligning with connected workflows, cloud-based technologies enable real-time collaboration and the seamless sharing of digital assets among remote teams, suppliers, and customers. “They eliminate the limitations of physical locations and enable global teams to work together efficiently. Cloud-based solutions also reduce IT infrastructure and maintenance costs, as the burden of hosting, security, and system updates lies with the cloud service provider,” explains Gemma Wood, Smartflow product manager, software, Loftware.

Furthermore, they often provide integrations with other cloud-based tools and services, enhancing the overall ecosystem and enabling businesses to leverage best-in-class solutions for different aspects of packaging production. “Cloud-based technologies are predicted to become more popular in the print industry, specifically in packaging applications such as project management, digital proofing, and digital asset management,” adds Wood.

Sustainability

Print on demand, digital printing, and personalization are growing as consumers demand faster turnaround times and tailored solutions. “This trend is a natural extension of the shift towards more sustainable practices, as it minimizes waste and offers an expeditious path to bring products to market,” says Julie Brannen, director of sales and sustainable solutions, Monadnock Paper Mills.

“Sustainability will be paramount as clients expect to work with businesses that have sustainability as a core tenet of their operations,” stresses Antinora.

Sustainability is expected to continue to be a central driver, with renewable, fiber-based alternatives taking precedence, particularly in products like gift cards, recycled packaging options, and styrene replacements. “Both consumers and legislation drive the demand for recyclable and non-toxic materials as businesses seek to minimize or avoid their use of non-recycled materials,” notes Brannen.

“Over the next 20 years we will continue to see a move to technologies that reduce the environmental footprint, albeit, not at any cost,” believes Philip Easton, managing director, Industrial Inkjet Ltd. He admits that the print industry is broad and diverse, in some sectors it will not survive e.g. newspapers, and others continue to evolve and grow e.g. labels and packaging. “The trend is towards more digital printing, this technology is still innovating and improving. It offers creative opportunity as you are not tied to printing the same thing for each imprint, has less waste for setup—both saving cost—but also improving the environmental footprint. The ongoing trend for more choice through more SKUs and diversity of products, but with lower volumes per SKU, again make digital printing the preferred technology.”

Eli Grinberg, CEO, Scodix, also believes that sustainability is a key focus, with increasing emphasis on custom, data-driven insights to inform decision-making. “By leveraging these insights, print service providers can not only track their sustainability efforts but also demonstrate to clients the tangible benefits of digital embellishment—such as reduced overproduction and optimized material efficiency—making sustainability not just a goal, but a strategic advantage.”

The consensus is sustainability will always be a strong trend in the industry. Harnett says manufacturers are innovating and exploring ways to make inks more sustainable while not compromising on print quality.

“Environmental and sustainable practices have requirements and regulations that are only going to get tougher, so businesses need to look at how to move more work from older analog offset production methods that are less environmentally friendly,” suggests Martinez.

Omni-Channel Marketing

It is important to accept that while print is not going away, its reach is limited compared with its virtual counterparts.

“While the industry is evolving, it’s clear that print itself will remain a vital part of the communication ecosystem. Print offers a tangible, tactile experience that many consumers still value, particularly in important communications like billing, compliance documents, and personalized marketing,” stresses Ernie Crawford, M-EDP, president/CEO, Crawford Technologies. “However, the future of the industry lies in its ability to integrate seamlessly with digital channels, creating a unified omni-channel experience for consumers.”

The convergence of marketing and traditional transactional communications is driving this shift. “Increasingly, CXOs and customer experience leaders recognize the importance of merging invoicing and customer engagement efforts into a cohesive strategy. This trend aligns with the growing demand for preference management where customers can choose how and when they want to receive communications via print, email, SMS, or mobile applications.”

Print companies no longer strictly provide physical documents; they are becoming data analytics experts. “By dissecting customer data, analyzing response patterns, and combining digital and print strategies, these companies help brands deliver personalized, relevant content. As a result, print providers that embrace AI-driven personalization and omni-channel communication will be well-positioned to enhance customer engagement and drive better results,” shares Crawford.

AI is also expected to play a role in customer communications. “There are numerous areas that will likely be affected like automating repetitive tasks—i.e., document composition, workflow automation, building more effective language in document design, efficient analyzing of data for predictive analytics and insights, predictive maintenance and capacity planning, enhancing revenue cycle management, and many more,” says Ryan Semanchik, president, Transformations, Inc.

Outside of customer communications management workflow, Semanchik expects AI to change how organizations operate other parts of their business. “For example, we use it internally to more efficiently engage with customer support queries by analyzing our full library of documentation and knowledge-based articles in seconds to instantly generate valuable responses.”

Intelligent Print

Print continues to evolve. New technologies, specifically AI, help print providers meet the growing demands of the ever-evolving print buyer. The ability to capture and interpret data help to optimize workflows. The ability to automate redundant tasks relieves pressure on skilled laborers. And, the ability to personalize and embellish print helps it stand out in a market crowded with messaging.

Dario Urbinati, CEO, Gallus group concludes that while we should continue to listen to the market and understand these shifts, “the only way we can ever really guarantee our survival and our success is to equip ourselves to adapt and change regardless of which direction the industry takes. We truly need to empower print business with the flexibility and agility to work in new ways, pivot, and adapt inline with these external forces.”

For more on this topic in our two-part Year in Review webinar series:

Part One: Featuring BW Converting, HP Indigo, Enfocus, Fiery, Highcon, and Komori discuss automation, inkjet, B2/B2+, digital for flexible packaging, new technologies, and more. Watch Now.

Part Two: Featuring HP, Landa, Muller Martini, Scodix, and Xerox discuss AI, robotics, sustainability, smart factories and more as we close out 2024. Watch Now.

Nov2024, DPS Magazine